zero night before christmas 3d models

241648 3d models found related to zero night before christmas.

prusaprinters

This design has been optimized to be printed without supports, and is divided into multiple parts so it can be printed easily. BEFORE YOU START:To assemble this camera, it is required to have printed all the parts and have the following list of...

prusaprinters

1000hrs you will have to do PTFE tube maintenance which is basically, pulling out the tube completely on both sides, cutting about 5-10mm of the hotend side (you will see, that the tubes colour changed to brow/black and the tube itself is getting...

prusaprinters

This kind of breaks the connector and exposes the contacts, but they will be protected by the case back later on.Before connecting the IDC cable to the display, split it into two like this. If you use a rainbow cable, it will be easier later on to...

prusaprinters

In order to do this, insert the motor, and put in place correctly, pinch the tube around the ring position and remove the motor, before dripping and rolling the super glue around carefully to avoid getting any inside the motor mount. If desired, the...

prusaprinters

links)4 AAA Batteries (each 1.2 V; 800 mAh)Shrink rap (I hardly used it due to too small diameter)Solder tinBit of copper wire (Stripped ethernet cable has solid core)3 V (3mm) LED (Colour your choice; Diode fit correct +/- orientation...

thingiverse

canon d'autelaltar canoncouper au centre de la largeur a 14 cm le 1 sur 3 le 2 sur 3 le 3 sur 3cut in the center of the width at 14 cm on 1 of 3 2 of 3 3 of 3attention vérifier avant impression au simulateur d'impressionsi tout vous convient ou...

prusaprinters

Violence is never more than a heartbeat away.Use those guns! Deliver your cargo!Stay in the fight!No Support!No Glue required!Stand up your Space Port before it's too late! ...(That's something else, sorry.)</li></ul><p><strong>Designed on...

prusaprinters

However, we must urgently avoid the IPA completely soaking the wall of the print: The part would then deform and the print would inevitably be lost:So take your time and follow my instructions.Before smoothing please attach the large ring to the...

prusaprinters

With the new PalletFork, I got the entire assembly running for just over 20 seconds at a time before kick starting the balance wheel by hand to keep it going! The biggest problem is the loose escapement gear and the frame is not held together rigid...

prusaprinters

To more easily see the direction the motor is spinning, install the motor pinion onto the motor shaft before soldering the motor. When looking from the shaft side, it should be turning clockwise.</p><figure class="image image-style-align-center...

thingiverse

Please stop the print just before completing the cavity for the nut or overhang (e.g., by using the printer's "filament change" function) and place an M3 nut or the "Ueberhang" part into the cavities. Then, you can resume the print. Some other parts...

sketchfab

The resulting blocks are cured in a controlled environment before being ready for use on site. Aircrete has several key benefits over traditional building materials. It's significantly lighter than concrete, reducing the structural load on buildings...

prusaprinters

I'd recommend that you design your enclosure iteratively, before attempting to print it. A visual sense-check in the renderer will tell you if the overall design is about right. When you slice the model for your printer, check a few...

myminifactory

- Weld the micro-switch cables (serial connection), it is preferable to carry out this operation before the pushers are glued, otherwise, it is difficult to position the wires, the iron is attracted by the magnets and its heat melts the Effector -...

thingiverse

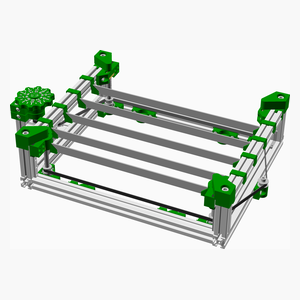

Level the bed by turning the thraded rods, before tightening the pulleys  [Top](#TOP) --- Finished! ... <span></span> ...

thingiverse

This limits the step generation to about 10MHZ before the CPU gets bogged down and begins to miss steps, this is with a single stepper too, divide that across 4 and you can quickly run into issues. This is with Marlin FW. Now on a board with a...

thingiverse

Double-sided Textured PEI Powder-coated Spring Steel Sheet before printing with PETG filament. For thin parts to stick correctly, you may need to adjust height of first layer perfectly and to reduce "Elephant foot compensation" from default value...

prusaprinters

When manually dialing, you must land on the gate with the exact roll count.When entering ANY gate, the player must draw a GateCard before traveling through the gate, and follow the instructions on the card. DHD:This is how you dial the gate to...

prusaprinters

It helps to use a thin tool to lift the cork away from the blowpipe body before inserting the cage leg.Do the same with the opposite leg of the valve cage on the other side of the pipe.And insert one more leg.Place the flapper with its smooth side...

prusaprinters

This cleaning Box will be always printed ...

sketchfab

In the world of Wolverine Inferno, the stakes are higher than ever before. With his adamantium claws cutting through flames and igniting even more destruction, Wolverine finds himself at the center of an all-consuming inferno. His determination to...

prusaprinters

(New in 2022-10-14 update.)Filament PM. This is a Czech manufacturer, well known to the older Prusa owners (as they provided the silver 1kg spool bundled with the Mk3 before Prusament times), that now also makes filaments for the “Made For...

prusaprinters

A reasonably strong blow is briefly at 3700 Hz before rolling back down as it slows. An average blow will be less than that. Perhaps around 500 Hz to 3200 Hz depending on how much air is blown into it. Please be careful with it and use it safely like...

thingiverse

A reasonably strong blow is briefly at 3700 Hz before rolling back down as it slows. An average blow will be less than that. Perhaps around 500 Hz to 3200 Hz depending on how much air is blown into it. Please be careful with it and use it safely...

prusaprinters

After drilling the holes you might consider painting it before attaching the hardware! ----How To Print---- Printing of Central Arch PartsThere are four parts: Large Arch which attaches the the central wood vertical beam and connects everythingBar...

thingiverse

Then run the following: import itertools x = [point[0] for point in Alien1] y = [point[1] for point in Alien1] coordinate_points_Alien1 = list(zip(x,y)) print(coordinate_points_Alien1) ``` As long as you have your coordinates in this order, then we...

thingiverse

I've read only an Spanish copy, so some details may be wrong because of translation issues and adaptations. Before printing anything, please, read this paragraph. I made this in various parts, depending on the scale, so they can be printed...

prusaprinters

Create an M6 thread with a tap, if you have one, before attaching the idler to the strut.Fix the rails to the inside of the Hex Body. Take care to install in the correct orientation.</li><li>Fix the touch latch at the top of the Hex Body using the...