prusa mk3s assembly 3d models

286410 3d models found related to prusa mk3s assembly.

prusaprinters

You'll need 8 of these. Assembly InstructionsOnce everything is printed follow the steps below.Please note, much of this will just push-fit and clip into place, but some parts such as the door handles, keyhole, and possibly the windows, may require...

cgtrader

Follow our tutorial for more information https://youtu.be/y1GaTiyj0oQ?si=hEQ3uAKvJVz6mNFa If you want to assemble several projects into one, please follow these instructions https://bit.ly/46JS63D This package included HDRP, URP, Built-In Shader, to...

thingiverse

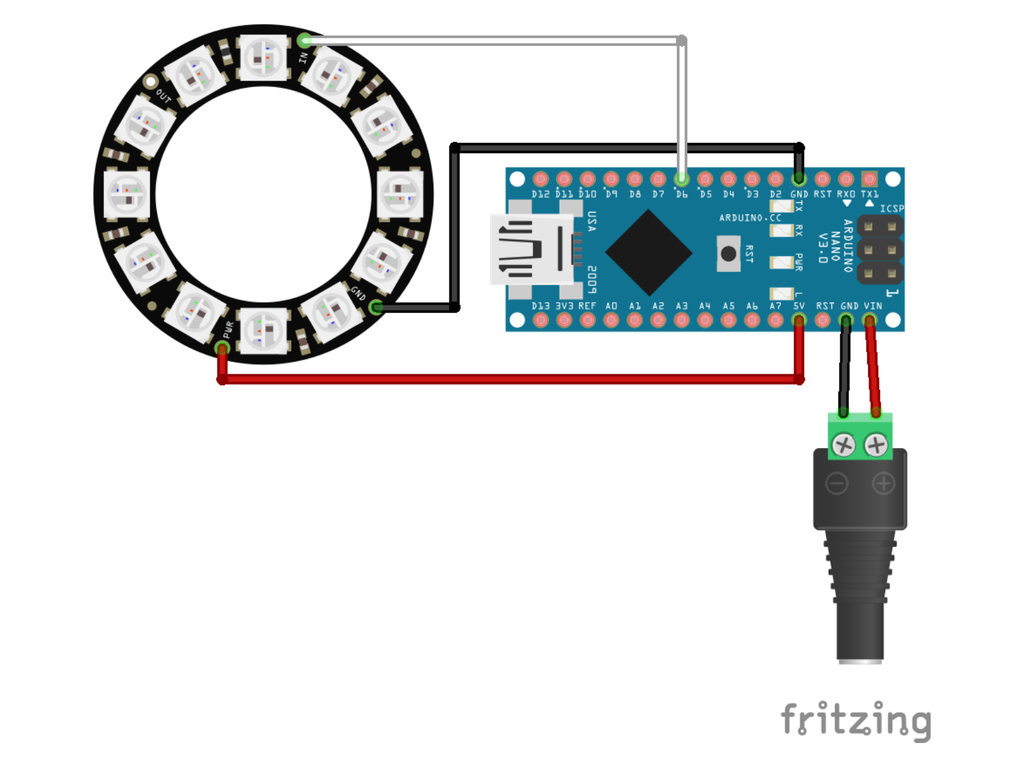

Assembly ------ Please use this diagram as a reference:  **Note**: It should not be necessary to use...

prusaprinters

(a 5mm Brim may be needed for the AXLE and RIMS as they print much taller than they are wide) -- COLOR CHANGES Specific Layer and Height in mm for each color change on each part, (NOTE using PrusaSlicer, Changes occur BEFORE the selected layer...

prusaprinters

The set listed in the BoM below has sizes that are ideal such as 3.2mm for pass-through bolt holes.Assembly:The pieces go together as shown in the pictures.The Layer Duct catch-hooks can be adjusted by filing material away or using super glue to add...

prusaprinters

For instance, the print-in-place hinge might fuse together. Assembly Instructions Step 1: Mark your magnets so you can visually verify the poles are oriented correctly when you are inserting them into the clip during the print pause. Be...

cgtrader

Follow our tutorial for more information https://youtu.be/y1GaTiyj0oQ?si=hEQ3uAKvJVz6mNFa If you want to assemble several projects into one, please follow these instructions https://bit.ly/46JS63D This package included HDRP, URP, Built-In Shader, to...

thingiverse

It may seem a little like a puzzle box, to assemble, screw the upper T-shaped bolt into the cradle body hole so the T-shaped side is in the same direction and lines up with the grooved upper printer bar slot, screw the two lower T-shaped bolts into...

thingiverse

Build instructions: For the (original) kit build instructions http://www.venatormfg.com/voltmeter-section-4-assembling-the-voltmeter.html When using CC LED displays change the code as needed, read the source code I have used slightly different parts...

thingiverse

You might be able to use fewer steps like two sizes but it's just harder I think or more steps but it's slower to get there.Of course all the plastic parts and screws to assemble it.You'll need like jumper wires and whatnot2@ 4x4 keypad modulesA...

cults3d

So, as you guess, the "bouchon-30" objective is closing the axis to maintain the machine's integrity after it's assembling. Axis are hollowed to manage a discrete storage that is a must have for an enigma ! Usage: Setup: First things first,...

prusaprinters

I used this one: https://www.ebay.com/itm/3-8-Carbide-Endmill-4-Flute-Flat-Bottom-Regular-TiAlN/133414909772?ssPageName=STRK%3AMEBIDX%3AIT&_trksid=p2057872.m2749.l2649SAE Size 016 O-Ring for each bushing - you can probably pick these up at any...

cults3d

With that knowledge in tow, I assembled a frame that was tall enough to support the gantry and had a garden box built in. I've included some rough designs in a 3d model for the framing, but you would need to figure out specifics on the frame...

thingiverse

ASSEMBLY. Print one peace each of the main body, the front cover, the speaker ring, and the little BT/amp enclosure plus 4 pieces of the feet (the last 2 being optional). Mount the speaker to the inside of the front panel and speaker ring with M3...

thingiverse

prusaprinters

Make sure the assembly is running smoothly, and if not, loosen the top screws and tighten as needed.Replace the hotbed onto the Y axis and level the bed, and move the Endstop mount if needed. Congratulations! ...Your Y axis is now upgraded to a low...

prusaprinters

Print the “B” versions of parts #2 and #3 (Lid and TFT Holder).The “A” version is recommended because the X and Y movement buttons on the TFT would be oriented / aligned with the actual axes of your CNC machine.Details of my upgrade of a LowRider v2...

thingiverse

After the glue is set, go back and run a thin bead on each of the fin roots Do the bottom first and then assemble the tubes and do the top. The top fins go to just the edge of the top tube. The bottom fins are set 19mm from the bottom of the bottom...

thingiverse

This is important to consider because this space is significantly more narrow than the inside of the rest of the helmet and will result in more open space within the helmet after assembly if scaled relative to the leather parts. This means you will...

thingiverse

PRINTING and ASSEMBLY. This should be a simple print. You will notice that the body has a 1 mm cover on one side. This is to give it more stability and make it easier to print and remove from the printer. No support or attachments needed. Print in...

prusaprinters

I also have HEPA room filter in the same room as the printer as a backup to this scrubber. Since I printed this, I made some minor improvements to the design (moved some mounting holes), but nothing that change the function or assembly process. I...

prusaprinters

There are no complete assembly instructions and you will have to create some parts yourself, even have to manufacture them. Be warned and do not begin the project until you are sure that you will overcome the following challenges:</p> <p>• Get the...

prusaprinters

Now, connect this assembly between the extruder and original ptfe tube. The short barrow end of the EasyCut connects to the original ptfe tube. Push together snuggly, check that all ptfe ends are well seated. On the EasyCut, ptfe tubing will cover...

prusaprinters

This repository contains everything to rebuild thesimplyRetro D8. TheD8 is my first attempt to build a small custom bartop from scratch. Warning This is a quite an easy build to print and assemble, but some of the screws are very hard to reach. There...

thingiverse

Assembly: - While you can just glue everything together I used a mix of gluing some parts and bolting the frames together. - Sand edges (or exacto) to remove all elephants foot expansion and fill/sand to your desire. Then paint pretty much all...

prusaprinters

And then post some makes and applications!ChangelogDangletag2022-06-12v0.6option for paper frame added2022-06-12v0.5minor improvements to carrier, housing and ring2022-06-10v0.4initial public releaseCustomize - your choices ring attachmentcord...

prusaprinters

Dispensers for 12oz, and 16oz hold 3.5 cans per-layer plus 1.5 cans on the tongue. Printing and AssemblyLine I decided to slice mine with a 0.6mm line width even though I was printing with a 0.4 nozzle. so I could get a 1.2mm thick wall...

thingiverse

I still need to assemble everything. ----- This is a remix of the nicely designed "SKR PRO case remix" by vandenmar: https://www.thingiverse.com/thing:4870495 Which was based on the "SKR PRo V1.2 + TFT35 E3 screen mounting box for MPCNC"...

prusaprinters

Heat Threaded Insert M3 - This will allow you to perfectly center all the elements of the Winder Spool HolderUse peel-off thread adhesive during assembly - This will prevent self-loosening of the screws caused by rotation and vibrationThe Winder...

prusaprinters

https://paypal.me/UnNamedGER Print Settings Printer Brand: Creality Printer: Ender 3 Pro Rafts: No Supports: Yes Resolution: 0.20 Infill: 20% Filament: Maertz Budget PLA PLA White Notes: Supports are only needed for the Roof without honeycombs ...