playmobil bunk beds 3d models

121768 3d models found related to playmobil bunk beds.

prusaprinters

Everything should print without supports but you might want to use a skirt to prevent lifting of the "Blades" and "Support" parts since the area of contact with the bed is small. I designed 2 slots at the base of the "Support" part to allow space for...

thingiverse

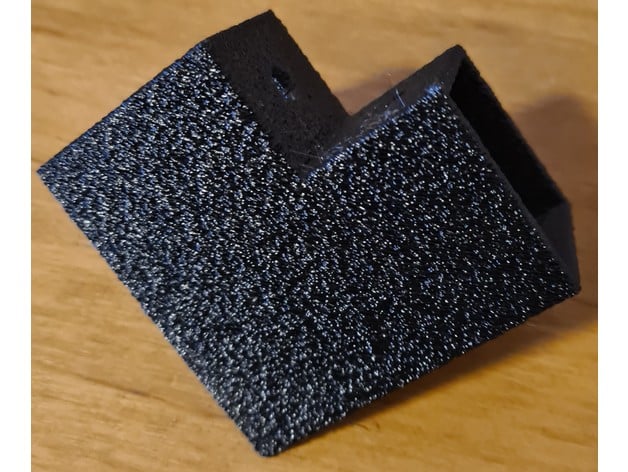

Since I have a textured print bed this fits perfectly together  After all parts are printed and the wood is cut to length and...

prusaprinters

I will left the links in a list here for the files with their inner diameter to...

myminifactory

46+ Hotend Brands and Models Supported:Anycubic Vyper V5 StockCreality Stock MK8 (2 screw mount)Creality CR-10S Pro (2 screw mount)Creality Spider (350c max)Creality Spider High Temp (500c max)Creality Spider 3 ProCreality Spider 4 Pro (Speedy...

prusaprinters

All of the parts need to be pretty flat, so if you don't have a heated bed, use a raft 3-4 mm tall.Press 2 bearings into each side, one bearing into each foot, and 2 bearings (stacked) into the eccentric. Use a vise or arbor press because you don't...

prusaprinters

I pushed then in just a little bit, then took the bed of my printer up to 70 degrees C and laid the part with the rails partially inserted upside down, to warm them up. I then gripped the rails with a needle nosed pliers a 1/2 inch from the part and...

gambody

You can pay with PayPal or your credit card.Also, you may like other Anime 3D miniatures._______FAQ: Where can I print a model if I have no printer?How to get started with 3D printing?How to set up my 3D printer?How to choose right 3D model print bed...

prusaprinters

Last step is to divide it up to fit on your print bed and cut-out pin recesses.I print from there, and as i assemble, I tweak my model as needed to make it better for then next person who prints.Its good to remember that plastic is melt-able and easy...

gambody

They will become a perfect match for your mech.________________________You can find detailed picture guidelines about how to use new joints in your model HERE.With the new joints you will get next advantages:STL files with new joints are already...

prusaprinters

All the chess pieces will NOT require support during printing. 6/1/2023 - Added two hinge test print STL files. Print settings:All the tolerances of this project was design to be printed using 0.4mm nozzle at 0.2mm layer height. Layer height:...

thingiverse

Minimum of 25% infill is recommended, as well as a full layer every 40 layers, mainly for toughness of the drawer front.If your printer has a moving bed on an axis (lots of printers) then the drawer must be printed with the front parallel to the...

prusaprinters

The top magnets have since been moved closer to the hinge for better springiness during clip actuation. Step 3: Press the magnets all the way into their pockets until the tops are flush with the top surface of the print, then resume the...

prusaprinters

The blades are printed with one side on the bed with transparent filament. To achieve the best effect, use a large nozzle with large layer height and line width. The hair is the most difficult to print. If you want a nice surface you need to print it...

thingiverse

As for now, we are currently working on printing these prototypes ourselves, ensuring everything goes smoothly off the print bed in actual physical test fittings. We will be posting pictures here to keep you guys updated on the progress of the...

thingiverse

I broke the large distributor into two parts so it would fit on my Ender 3 print bed. I simulated both distributors in CFD and they do a very good job of spreading the flow. I meant for this box to also serve as dry storage for filament while...

prusaprinters

I pushed then in just a little bit, then took the bed of my printer up to 70 degrees C and laid the part with the rails partially inserted upside down, to warm them up. I then gripped the rails with a needle nosed pliers a 1/2 inch from the part and...

prusaprinters

the feet and cable cover will be needed to finish the build, i usually print them along with the top left, since it leaves the center of the print bed open. c. the screw inserts are only needed if you could only find M4 x 16mm screws (sometimes the...

prusaprinters

To get stronger spokes you can print them laying flat on the bed but this requires supports. Also the friction fit changes when printing parts in different orientations.</p><h4>Infill</h4><p>The hub isn't critical, I usually print it with 13 %. Note:...

prusaprinters

Depending on your wiring style you can get some pretty nice looking effects with this logo and the use of an NodeMCU controller.The model is in two formats. One for those who have a large format printer and can print the entire model as...

prusaprinters

If the bed has a chance to cool then the logo layer could lose adhesion and get messy when the lid gets printed around and above it.Remix Credits and ThanksBased on Whity's excellent “Rugged Box (Parameterizable)” as a base model, which made...

prusaprinters

It gets accurate time through NTP and lights appropriate LEDs (WS2812b) to cast a shadow indicating the hour. Print instructionsThe Clock The creation and how it works can be seen in the video: It proudly hangs above our bed, it seems very bright...

gambody

You can find them at the end of the list._______FAQ: Where can I print a model if I have no printer?How to get started with 3D printing?How to set up my 3D printer?How to choose right 3D model print bed positioning? How to paint printed figurine?This...

gambody

You can pay with PayPal or your credit card.Also, you may like another Space War 3D models._______FAQ: Where can I print a model if I have no printer?How to get started with 3D printing?How to set up my 3D printer?How to choose right 3D model print...

prusaprinters

Replicate it (or load it twice) for the other half, arrange them on the bed, then slice and print them.PLA is recommended, as it was used to test this model.At least 3 walls should be used, more for larger pipes or heavier loads.Use a strong...

prusaprinters

I find that functional prints like this are best produced hot and slow – I print at 45 mm/s at 245 °C nozzle and 80 °C bed temperature with eSUN PETG, on the Prusa textured PEI powder-coated spring steel sheet.Estimated print time with these settings...

prusaprinters

Depending on your print surface and your bed adhesion, you may want to put a raft (with a 5mm margin - no more is needed) under it. But I've printed ten of these, on glass, out of PLA, and only had one failure out of ten. </p><p> </p><p>The...

thingiverse

Material: PLA (or any other rigid filament) Bed Adhesion: No (unless you need it) Walls: 3 or more Infill: 30-100% (make sure they're reasonably durable). #### Print instructions for remixed parts can be found in originals: - PTFE Tube Cutting...

prusaprinters

One designed for a multi material, or dual nozzle printer, the other for a single nozzle printer with a filament change required.The skybridges should be printed like the building pieces, with the open side facing down, and a raft is...

thingiverse

Bed Levelling UBL 5. Load filament and print an XYZ cube to make sure it is properly configured Materials Summary =============== 10 x M3 threaded brass inserts (6 x effector arms, 2 x magnet holder, 2 x Volcano magnet holder) 5 x Flat capped...

prusaprinters

Post-Printing In addition to the supports added by your slicer, the gear box has a ring and a set of little vanes about a centimeter tall at the bottom end, just there for the purposes of bed adhesion. Cut them off if so desired - they shouldn't get...