minitec frame 3d models

122138 3d models found related to minitec frame.

prusaprinters

Please only attempt this if you are very experienced in 3d printer frame upgrades and modifications. Everything except the Z endstop will print without support. ...Add heatset inserts to the ballscrew mounts and X motor and idler pieces as needed, also...

prusaprinters

It passes through the pivot bracket, prop arm, pivot backer, and into the window frame. Drill a hole that is nearly the diameter of the nail that you are using. 1/8" is slightly too wide for a standard 8D nail. The nail should fit in the hole...

prusaprinters

One of each cut: 5'' x 3 3/8'' 5'' x 3 5/8 5'' x 3.925 5'' x 4 5/16 5'' x 4 3/4 Misc 1 Roll of Cork Padding for Grip 1 22mm 608 Skate Bearing\Fidget Spinner Type 2 53/64 in 3'' Compression Spring 2 12ml Syringe and Tube 1 18" Bungee Cord 1 1'' 36''...

thingiverse

The system has about 15ms of measured lag, which is about 1 frame in a game. The base station appears as a game controller for a PC. Building the wireless system requires some electrical skills. The wireless side was developed by me and my friend...

prusaprinters

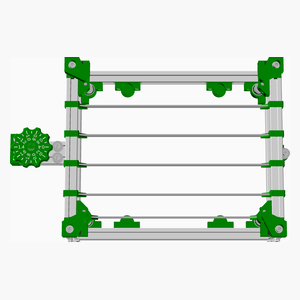

I did just make them to show how the frame look like. Printer settings:Infill- 36% Grid patternPerimeters- 4Hight- 0,2I needed to use XY compensation +0,2 on my printerHAPPY PRINTING! You need: 4 props where 2 is CCW and 2 is CW12pcs M3x8mm...

cults3d

Used screws, nuts and washers: Extruder: 3x M3x35mm (original) RunOut sensor: 2x M3x16mm (original) 2x M3 hammer nuts Frame mounting: 4x M5x20mm 4x hammer nuts M5 4x washer M5 Connection: 4x countersunk screw M3x14mm 4x self-locking M3 4x washer M3...

thingiverse

... and connect the arms together. Pick up the spool + holder, keeping it all together and attach both arms to the top of the frame at the same time. ...Be sure the spool is hanging towards the back of the printer, otherwise the extruder can hit it.

prusaprinters

The only problem I have had, is when doing a Z calibration and the extruder moves to the top of the frame, the filament will push up into the container and can slip over the edge of a full filament spool. This can be prevented by holding the filament...

thingiverse

The most notable changes are: - Integrated battery tray to make frame tougher and stiffer (and save a few grams). - better Balanced reduce propwash. - Stronger arms but less wight (only 21 gram) == Easy Printable == If you need better...

thingiverse

If you want to build the clock as shown you will need the following parts in addition to the above: 2x printed STL Back-Mounting-Frame 1x printed STL ArdNano-Case 1x printed STL Stands This will fit an Arduino Nano or Pro Mini and a small DS3231...

thingiverse

I had long wanted to make a dual extruder/multimaterial setup on my printer but the Geeetech i3 Al is limited in this regard in that its frame size is quite small compared to other 200x200 printers. A normal idex or dual extruder setup using the...

thingiverse

Two M5x12 and two M4x12 countersunk head screws are used to fasten the load sensor to the base and top frames. The case uses a couple of M3x12 screws. Depending on your setup, you may notice some spring in the scale which will vary your weight...

thingiverse

If you plan to relocate your PSU to the side of a cabinet, keep in mind that the unit has mounting holes matching the socket head cap screws originally used to mount the PSU to the Ender 3 frame. These are M4 x 0.7mm screws and can be found at most...

cults3d

The curls on the head join those of the beard to frame the emperor’s rather pensive face. A laurel wreath crowns the head and separates the deeply worked curls from a flatter swirl of hair above the wreath. Technical examination has revealed that the...

thingiverse

Attach the top extrusions to the rest of the frame.  <span></span> [Top](#TOP) --- <a...

cults3d

I will try to help :) UPDATE 20 IX 2021 Version 1.1 with beveled holes in base and top parts (will help if your first layer is squished) and with very small ridges on bars and inside base and top (lanter will hold together stronger) New version of...

thingiverse

Use two video camera's synchronised (started) at the same time so frame rates are constant, have one camera aimed at the start tape and the second camera aimed at the second tape 3 meters away. We also managed a distance of the full length of the...

cults3d

The rescaled version is then loaded to Fusion360, where the base profile is extruded in negative direction -0.6 mm and the white parts inlcuding the frame are extruded to the positive direction +0.6 mm. Lastly I added colors to the faces of the sign...

myminifactory

The face was located in the door embedded in a rich frame hammered in with pegs. The mechanism was hidden inside. Just like in a house the heart beat inside. This form was a kind of advertisement for Podhale architecture. When looking at the metal...

prusaprinters

Screwing in the fans will also add the necessary rigidity to the frame.The Barrel connector and the PWM controller both have printed compartments for them.You can glue them in with hotglue for example. Just keep in mind that in order to reattach...

thingiverse

* 1911 - INNER FRAME.stl 20% infill. * 1911 - LEFT GRIP.stl * 1911 - RIGHT GRIP.stl 20% infill for both grips. If slicing results in an unsightly single or double width line as the last layer you may want to cut the last couple layers off...

thingiverse

It is also lightweight and portable, can be disassembled fast, and takes up little space (thanks to the IKEA GUNDE chair used as a frame). Construction allows high precision with Hall effect sensors, smooth stick travel, and no backlash, thus...

thingiverse

Re-apply the M5 screw that was holding the frame. 6) Tighten firmly the screws on the rail bit by bit. Do one revolution at a time on every screw before going back to the first screw to avoid horizontal tension on the rail. 7) Re-attach the...

thingiverse

Some of these parts require cutting part of the OWI-535 frame, which is a non-reversible process. Be certain you want to do these modifications before cuts are made. Additionally, most of the motors will require their wires to be extended. Design...

prusaprinters

Really like the wheel from TheSloppyApprentice's Watermill and was looking for ways to hold it besides that large frame in the source.So I could make it stand in a bassin or hang under some opening where water is dropping off.So here are 2...

thingiverse

The quick release GoPro frame is actually based on an SJ4000 clone and fits the SJ4000. I do not own a GoPro, but feel free to re-mix and adapt any of these parts to fit and work with your camera. The rail mounts (20X20 and 40X40) are simple clip-on...

thingiverse

Completely OPEN SOURCE (all the design files and control code are fully available for everyone to modify or adapt it to its needs) and with a 3D printed frame. It can hold: small cameras, laser pointers, flashlights, toy guns, a stick…. Everything...

thingiverse

- Loosely secure the MGN12 rails to the frame. - Attach the y-carriage mount and ensure squareness by pulling the bed all the way to the front and tighten a few M4 screws to secure and then the rest after. - Slide the y-carriage back and forth...

thingiverse

The two frame holders for the Y and Z chain were taken from the Switchwire project and slightly adapted. Use **threaded inserts** in the chainmounts. For the hinges you need **2x MR95** miniature ball bearing each side. Now I'm trying to...

thingiverse

This is because, just like the screen caddy, my original designs for the motherboard mount, backplate, and partial frame were accidentally deleted by our IT guy. (You can see a large part of my original layout mATX layout in the first video of my...