minecraft sniper texture 3d models

542711 3d models found related to minecraft sniper texture.

prusaprinters

That is why I would recommend either using the textured sheet, or some type of release agent on the smooth sheet. Using The stl Files Additionally, I have included three stl files. One is the main body, one is the screw-on filter cap, and the last...

prusaprinters

If you have one, I would highly recommend printing it on a textured PEI sheet without glue stick, which makes it very easy to remove the print without damage.If this helps you, please consider giving it a like, I would appreciate that a lot!Versions...

thingiverse

These buttons are much harder to find just by touch (if you have this need, you could remix the buttons with some texture on top to help with this), but they are plenty easy to press even though they are flush with the case. * The original button...

cults3d

This opens up new possibilities for creating unique textures and finishes that can add an extra layer of depth and visual interest to the skull ring design. Overall, the combination of cutting-edge technology and creative freedom offered by 3D...

prusaprinters

The wires run under the foam.The general process:take the rough foam pieces and glue them on using hot glue, scar the parts that are intended to become roads to give them some textureadd other stuff like small rocks, sawdust, etc.mix wood glue with...

prusaprinters

It is now tuned for PETG filament, Bambu Textured PEI bed and printing on the P1P. If you are printing with other types of filament/printer, update the settings accordingly. Please read the user guide, which will provide you with information to help...

thingiverse

It's best to print on a very smooth surface, such as glass or a smooth PEI sheet, rather than on a textured surface. The surface of the mask that prints in contact with the print bed will touch the negative, so any roughness could scratch your...

prusaprinters

And please post your makes to help others! Print Settings Printer Brand: Prusa Printer: I3 MK3S Rafts: No Supports: No Resolution: 0.15 (0.4 nozzle X) Infill: 15 Filament: 123-3D Jupiter series PETG Carbon Fiber Black Notes: I used my Prusa to print...

prusaprinters

O-rings13 - 4-40 x 1/4" screws1 - 4-40 x 1" panhead screw1 - 4-40 nut1 - #4 washer1 - Standard poker-sized deck of cards (textured finish cards work best)All parts were printed in PLA with 0.2mm layer thickness, 3 perimeters and 20% infill. Use a...

thingiverse

Print 1 of every part except the following: * canopy halves (outlined above) * I recommend printing it in right-left halves for ease of assembly and to keep the layer lines going the same direction for sheen/texture (assuming FDM printing) * 2x wing...

prusaprinters

Important note - After each panel you print check the holes with a screw again so you can compensate for it as you go. I printed on the glass side on my bed (not textured) so the print comes up glass like on the outside. Information about assembly:...

prusaprinters

These buttons are much harder to find just by touch (if you have this need, you could remix the buttons with some texture on top to help with this), but they are plenty easy to press even though they are flush with the case. + The original button...

prusaprinters

I printed on the textured sheet by Prusa and didn't need any brim.Activate “detect thin walls” in PrusaSlicer and make sure that the thin verticals support layer is sliced correctly (see picture) ASSEMBLYDisassemble one KLAMBY. You only need the...

cgtrader

Goat_breast Contains 17 objects, 6 materials, 8k texture. Blend, blend packed, obj, fbx Goat body: triscount 14972, polycount 11300, vertexcount 9400. Tapes_hands triscount -1213, polycount -718, vertexcount -636....

prusaprinters

Spring Steel Sheet with Smooth Double-sided PEI before printing with PETG filament.Water: WaterCleaning Agent: 2-Hexoxyethanol, Isopropanolamine, Ammonium HydroxideWetting Agent: Lauryl Dimethyl Amine Oxide, Sodium Dodecylbenzene SulfonateFragrance:...

prusaprinters

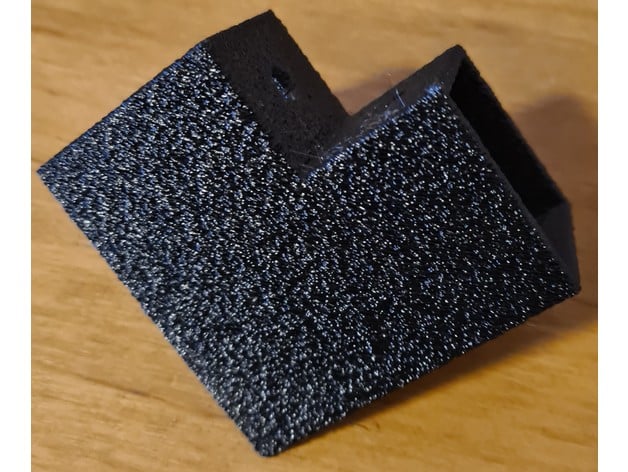

... layers, 60° bed temperature, outside perimeters first. I turned the model 35° anticlockwise, then set the seam position to ‘rear’. The texture on the side panels comes from this textured bed plate, and I used the Tecbears black PLA.

prusaprinters

The parts are made to fit to it only.)1x ESP32 micro controller board (No ESP8266 use possible because of its low specs.)1x USB power supply 5V / >=3A1x Micro USB cable 3m Printing instructions:No supports or brim needed for all parts.0.3 draft...

prusaprinters

Spring Steel Sheet with Smooth Double-sided PEI before printing with PETG filament.Water: WaterCleaning Agent: 2-Hexoxyethanol, Isopropanolamine, Ammonium HydroxideWetting Agent: Lauryl Dimethyl Amine Oxide, Sodium Dodecylbenzene SulfonateFragrance:...

prusaprinters

Spring Steel Sheet with Smooth Double-sided PEI before printing with PETG filament.Water: WaterCleaning Agent: 2-Hexoxyethanol, Isopropanolamine, Ammonium HydroxideWetting Agent: Lauryl Dimethyl Amine Oxide, Sodium Dodecylbenzene SulfonateFragrance:...

prusaprinters

for TEXTURED PEI Powder-coated Spring Steel Sheet.For BIG parts to stick on TEXTURED PEI Powder-coated Spring Steel Sheet, I increased recommended bed temperature from 60-80°C (for AmazonBasic and MCPP BasicFill PETG filaments) to 85°C (First layer)...

prusaprinters

While I love the look of prints from the textured sheet, it just doesn't look right for this particular model.The model has two gCode files. The first file is the back of the TV and the other file is the front of the TV with both dials (this means...

thingiverse

Brick texture will be a huge pain, and I haven't done doors or windows yet. Maybe I'll do those soon, maybe someone else can contribute. I haven't tested the 180-degree walls yet, but 90 seems to work fine. The curved handrails are also untested. ...

prusaprinters

Made this one for the wife sewing room from some color changing filament. Print instructionsgenerated by PrusaSlicer 2.1.1+ on 2020-01-07 at 12:29:45 UTC avoid_crossing_perimeters = 0 bed_custom_model = bed_custom_texture = bed_shape =...

prusaprinters

I find that functional prints like this are best produced hot and slow – I print at 45 mm/s at 245 °C nozzle and 80 °C bed temperature with eSUN PETG, on the Prusa textured PEI powder-coated spring steel sheet.Estimated print time with these settings...

prusaprinters

You need the strength of PETG to hold the weight of the buffer unit, cassettes and brackets.- Print using MK4 or MK3S+ printer with Hardened steel Nozzle 0.4 mm, and Textured Plate.- Print inside the enclosure, or warping may occur.- Use standard...

thingiverse

Since I have a textured print bed this fits perfectly together  After all parts are printed and the wood is cut to length and...

cults3d

But at this point it you wouldn’t need, it unless that is the texture you are needing. OH!!! Almost forgot Material flow rate, now this will play a part in a couple areas. First it will affect your tolerance between parts, surface quality (all...

prusaprinters

because I wanted to and I had a lot of fun doing it :-).I tried to achieve the following key features:Easy to print without support (no steep overhangs or long bridges and stuff).Top and bottom layer printable on print surface (so I could make good...

prusaprinters

Make sure to test that the heater power won't cause trouble even if (all) fans completely fail, even after many minutes of fan failure while the boost heater is still powered.PC Blend or Polymax PC-MAX is strongly recommended (I've tried both;...

thingiverse

- It will flex a little bit, but not enough to wobble when fully assembled and printed correctly - It won't feel like higher end aluminium cases because it's plastic - You'll need to do a good job cleaning up all the orifices and vents before...