m17 threaded barrel 3d models

127445 3d models found related to m17 threaded barrel.

prusaprinters

I had most of the parts in stock so personally this conversation cost very little.3.The forward idlers are created by removing the front to M5 2020 frame fixings and replace them with a 80mm threaded bar. This is a very simple but strong foundation...

grabcad

Top and bottom covers secured with nuts and bolts, instead of threaded through holes, which can be damaged with dirt.5. Heavy gauge extruded aluminum reflectors with high gloss reflective finish. Resists dents and corrosion.6. A wrench is used to...

thingiverse

* Feed a screwdriver through the post from the bottom to hold the screw in place and begin screwing the M3 Nuts over the threads. Do not over-tighten. Hand-tight is fine. ------------------ # Heat-Set Insert Version ####...

prusaprinters

I like to keep the river/track tiles in their inserts during the game (that's why I made them separate from the bigger inserts). Wood piecesAll wooden pieces (beer barrels, iron, coal, player pieces) are kept in a box that also holds the player...

gambody

The inspiration for the creation this Tank was books and it was spent a lot of time to repeat all the details of the Tank as in real life.ABOUT THIS 3D MODEL KITThe model is saved in STL files, a format supported by most 3D printers.Features of this...

prusaprinters

This model includes both a solid and a honeycomb version whether you want to print a more authentic and traditional version of the warlock or if you want it to be more unique. I used absolutely bottom of the barrel parts to get this to a fully...

thingiverse

**Note:** The head can still be powered completely using POE including supplying 7.5v power to the camera system through the Barrell Aux port this has not changed but the limitation is the Max 30W draw. The parts now allow for two variants of...

gambody

A barrel that is as a part of the platform can be assembled either with a simple lid or flames for you to choose from. Joel figurine can be showcased holding either of two weapons - the rifle or flamethrower - leaving the other on the back, hence two...

prusaprinters

Upload the “firmware”(which you can find on github here: https://github.com/fluetke/sandclock_fw)9.Solder wires from your dc-barrel-jack onto the RAW(+) and GND(-) pins of your arduino, then connect your Arduinos VCC, GND and the motor pins you...

gambody

There is a flat tyre half-buried in a snowdrift and a barrel that you can display either with fire inside or covered with a lid. We are pretty sure you think the platform is a tad too big for a lone girl. Right you are because there is Joel figurine...

gambody

The 3D printing fighter is equipped with laser barrels, a power harpoon and tow cable, a cockpit for a pilot and a gunner, and even has “ZZ” ID markings on both sides of the canopy. Also, the 3D printing model of T-47 Snowspeeder comes with a...

prusaprinters

Assemble the Stem – Upper and Stem – Lower components by threading them together. </li> <li>Route the wires through the Stem – Upper, making sure to not to pull the wires all the way up. </li> <img alt="Servo" height="600"...

prusaprinters

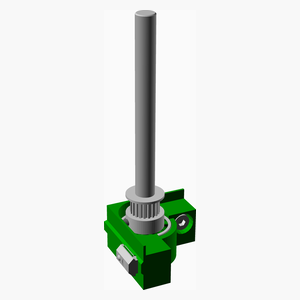

200mmIn the picture (D & E) you can see i drilled a hole through the axis (threaded rod) to fasten the gears. In that case you need 2 x 20-25mm M3 bolts and locking nuts. You can also use the holes in the gears for grub- screws (less secure,...

prusaprinters

On the left, one grub screw is vertical while the other is orientated towards the front.When the alignment is all good, use a bit of Medium Thread Lock and tighten the grub screws.Thread the belts through the rear brackets while access is still easy....

prusaprinters

Excessive stringing will also clog the threads and prevent the SPA from working properly (it may be VERY difficult to adjust once installed).The modified extruder body should be printed in PETG at a 0.2mm layer height with 20% grid infill (this is...

prusaprinters

So it was easier to more clearly see its contents without the need to open it.Fine tuning the joints and threads seems to be the most difficult part of assembly. The effort here depends on how accurately you calibrated your printer and filament. It's...

prusaprinters

You may need to print at a lower temperature and increase cooling if the threads look messy.A small dab of grease on the oscillator gears and screw may help, but I haven't tried. ...Don't grease the main/motor gears, as it'll just fling out and make a...

thingiverse

Put the pulley loosely onto the threaded rod and insert them into the ball bearingpulles.  ...

prusaprinters

Just attaching straps to the ends would stress the fasteners and plastic parts of the chest. Thread the first strap:Thread the strap from the outside to the inside on the top hole, then back out the bottom hole. Pass the strap under...

prusaprinters

There is enough space to thread the cable through rift above to reach the stepper motor, just like on the second photo.Having that part done, move to the other side of the machine. Take Z_motor_mount_R and screw new stepper motor to it. For now...

prusaprinters

Narrow computer fan screws (with blunt ends and very coarse threads made for cutting their own threads in plastic) 1cm-long and 3mm diameter would be ideal if you can find them (note that these are smaller than the most common...

thingiverse

NOTE that the threads go in the OPPOSITE direction from normal threads. You will need to turn the wheel COUNTERCLOCKWISE to attach it. This is to keep the wheel from unscrewing itself from the hub during operation. You can print and use the hub...

prusaprinters

See the YouTube video for assembly hints; the idea is that the accessory thread adapters replace the nozzles so that you can use the accessory pipes instead. 2x Lock Collars, 2x 30-degree accessory adapters, 2x elbows, and the F-F...

prusaprinters

Perhaps printing the design from the side will reduce it, but the threads and holes may not come out correctly. Optional 2:If you want to eliminate problematic elements like the coupler, I think it is possible. You would have to put a new...

cults3d

No changes to the Z axis stepper motors or threaded rods are necessary because the X gantry’s motor and idler mounts are inverted to account for the shorter threaded rods, that combined with taller Z axis top brackets to capture the taller linear...

prusaprinters

Ensure the nut sits tight and secure, use some superglue if needed.Add some superglue to the inside of the Lid knob-top and press the top and bottom firmly together, don't forget the spacer, to make the complete Lid knob.Take the Chamber lid and...

prusaprinters

Line up the door holes with the holes in the small gears; this will require adjusting the thread position to line up the holes vertically. Then screw in all 7 doors onto the small gears. Make sure these are tight to make sure the mechanism moves...

myminifactory

This should be a press fit, however, depending on the printer and chosen resolution, if it is not, it is recommended that this is taped in place. The other wing nut(6) is then threaded onto the carriage bolt in the same orientation as the first,...

prusaprinters

This will be the most tedious part of the installation, especially for MK2 users (due to threaded frame rods changing alignment after tightening [Protop: this process also just happens to be the best method to align the Y axis smooth rods, even if...

prusaprinters

You will need to drill 4 highly precise holes in a new or existing Taz 3-5 heated bed mount plate to accommodate the Openrail hardware. Build thread is here: https://forum.lulzbot.com/viewtopic.php?f=16&t=2426 Video of the completed modification...