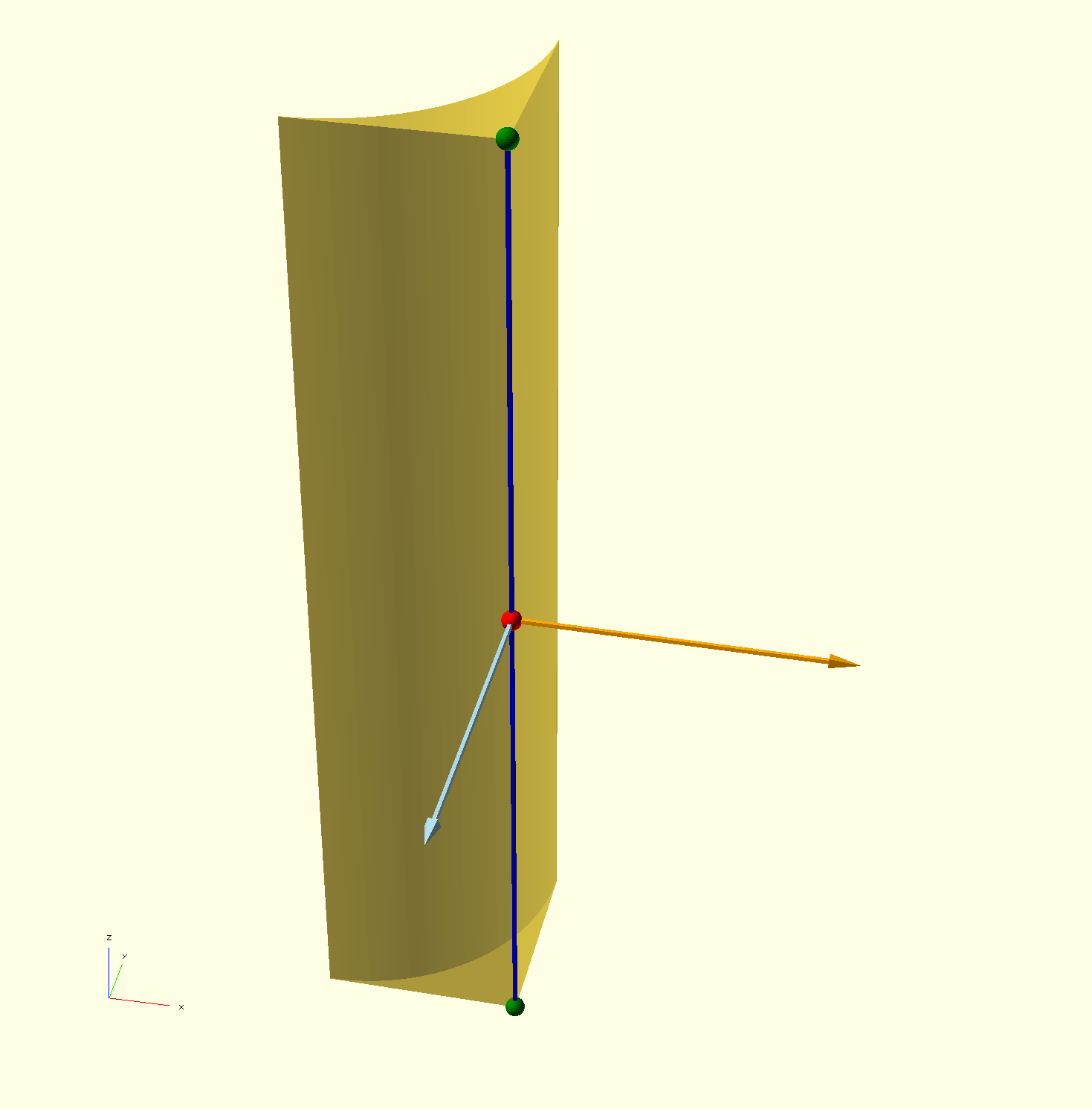

line integral mathematica 3d models

313159 3d models found related to line integral mathematica.

prusaprinters

the object here is to reduce the layer lines and heavy marks to prepare to fill the imperfections.You will see how good your layer alignment really is in this stepDisassemble and Fill all the surfaces with glazing puttyDisassemble the top and bottom...

prusaprinters

You will not need these as we will be using a different, high torque clock movement.Enlarge the central hole to 18mm. Slice off the original clock hanger so a fixing/blanking plate can be added later. Insert the large 6002 bearing into the...

myminifactory

In this case, you won't need the "line-changer actuator" in the car but you will need electronics under each lane-changer track part, specially the "sensors" and the "actuator". There is a very good thing about the InfraRed lane-changers... You can...

thingiverse

Ensure the BIOS switch is in the correct place when you reassemble the keyboard so it lines up with the actual switch. **THERE ARE 2 HIDDEN SCREWS TO TAKE THE BOARD APART, 1 UNDER THE LOGO ANOTHER UNDER THE RIGHT VOLUME KNOB COVER** That massive...

thingiverse

This light can be eliminated by lining the piano walls and cover with black electrical tape (This is easier to do before you wire the entire piano). There is a cover for the mini-USB port with the Hammond logo on it since Schroeder's "piano" sounds...

cults3d

They will cause the tight tolerance of the design to fuse the edges or even overlap lines that should not be Hence how this model can test for tolerance and backlash. Backlash is a little more difficult to resolve (well not difficult but at least a...

prusaprinters

I used this to get my (currently) world record bedslinger #speedboatrace benchy at only 4m 48s.After trying other people's designs and having issues or bad performance as they always lacked something or another, I finally decided to design my own X...

cgtrader

We have included some software features-for example, the lining of one of the sneakers shimmers when running. Convenient switching of clothing parts via Construction Script. Fully customized physics of the character. Simulation of hair, clothes, body...

![PaScn3D Mk.0 - 3D Scanner [PrusaPrinters Contest Edition]](/img/img-not-found.svg)

prusaprinters

If you have a printer, then you have such electronics! PaScn3D connection to Prusa 3D printer in a minute (tested!) – dedicated mounting brackets, components adapted to the dimensions of the device Modularity – adaptation to other printers without...

thingiverse

This will be to tie a length of Kevlar line that goes to the parachute and nose shock cord. Bore the hole as close to the top ring as possible. 2mm or 3mm max. I have started putting a drop of CA on all Kevlar knots - I had two unravel on the same...

thingiverse

Full description about the FW and downloadable files here: https://github.com/kisslorand/BTT-TFT-FW If you like the extra work done or if you want to contribute to further improvements you can buy me a coffee here:...

thingiverse

However, there are indeed many flaws with this original design and process, tinkercad has a tendency to leave small gaps and unwanted artifacts in the final .stl exports, also the curved line ability in tinkercad is very limited and results in split...

prusaprinters

Line the surface said pin flush with the surface of the clamp (the part of the core with many holes will have a gap to the surface of the collet clamp). Then, insert the M3 nut & screw into the provisions on the side of the collet clamp and...

prusaprinters

You will need to put together the following Sub assemblies:2 x BackLeg_SA2 x FrontLeg_SA2 x TopLink_SA2 x BottomLink_SA5 x CrossSupport_SAThe 3D printed components, with or without nut...

prusaprinters

Just set your perimeter size(s) and single extrusion behavior, slice the file, and the slicer's preview willl give you a graphic readout of (1) what thickness will be too fine to be printed at all, and (2) where the boundary between perimeter...

prusaprinters

(LxWxH) Cam box pieces should be 0.30cm thick. Cam gears should be no thicker than 1.50cm. Thick blocks should be no thicker than 1.50cm. Camshafts should be no thinner than 0.50cm in any dimension (L, W, or H) Parts MUST begin with a constraint box,...

thingiverse

I'm going to redesign it because I made this to bolt to the factory mounts for the Qidi mainboard and line up with the side opening on that printer. My intention was to have the Lerdge connections be accessible from the side like the factory and so I...

prusaprinters

Mark or scratch with a dot or a line the same polar side of all 12 of the magnets. It doesn’t matter which side (positive or negative) that you mark, just as long as you’re consistent and mark all of the same sides.</p><p>BASE: Glue in place 4...

prusaprinters

Line up the mount holes with the hole in the back of the rear chassis and secure them using 4 flat head M3 screws. Secure the Motor into the Motor mount making sure the pinion has good contact with the main gear. Test out the differential by...

prusaprinters

To achieve the best effect, use a large nozzle with large layer height and line width. The hair is the most difficult to print. If you want a nice surface you need to print it in the orientation as it is designed, but that requires a lot of supports....

![JGAurora A5 E3D drag knife mount [vinyl cutter]](/img/img-not-found.svg)

prusaprinters

300x300 mm² sticky pads that hold on to the vinyl)20 mm rubber band or the printed spring2x M3x8 hexagon socket head cap screw2x Ruthex RX-M3x5.7 threaded insertsPrint SettingsPrint all models in their provided orientation with 0.4 mm nozzle, 0.2 mm...

prusaprinters

the point of the thread) on either side. Then, update the Expression value in the ConnectDiameter row (the box highlighted yellow below) with this found value.Connector Length - Measure the height (in MM)...

prusaprinters

As it gets closer to the joiner piece line it up with the faces of the top plate and screw them on together. Screw it only finger tight initially. Now take a 17mm spanner and hold the nut on the bottom of the basket and gently tighten the top plate...

cgtrader

We have included some software features-for example, the lining of one of the sneakers shimmers when running. Convenient switching of clothing parts via Construction Script. Fully customized physics of the character. Simulation of hair, clothes, body...

prusaprinters

Just line the USB-C up with hole for the cable and stick it in place. </p><p>The Proton-c is attached with two M2 screws (upside down)</p><p>Solder or otherwise connect the pins for the rows and columns (tidy your wires), the LEDs to a...

prusaprinters

https://www.easy-grow.co.uk/products/reflective-sheeting/diamond-lightite/Put 4 pcs Felt Pads on the bottom of the electronics case to help ventilation.How to prepare the GrowBox for the first plants:Pair the Blitzwolf switch module with your wifi...

prusaprinters

Use 5 M3*10 screws. OK, we enter the finish line, slowly... Mount the 4th servo to the "left" part. Axis point to the front, but downwards. Connect OK fingers and "assholearm" together using another M3*10 screw. Mount the whole arm to the servo. DO...

thingiverse

Make sure these details are in line with your expectations before proceeding with the print. Make sure to confirm the measurements and price of the "Base for Sundial" model, material ID 72 at...

thingiverse

They are already painted on in the provided .3mf files, but if you need to repaint them, I use a 3mm circular brush and paint a line along the center of the bottom, except where the cup is.90º ConnectorThis is a small connector where the ball and...

thingiverse

In the above image: - The blue line is the edge (corner) that you want to smooth, where the two faces meet. - The <span...