kalis teeth 3d models

24748 3d models found related to kalis teeth.

prusaprinters

SLOT 290mmHardware parts:16 pc - M3x10mm socket button head screw4 pcs - M4x15mm SH (socket head) screw4 pcs - M4x20mm FH (Flat head) screw4 pcs - M4x10mm SH (socket head) screw4 pcs - M5x35mm FH (Flat Head) screw14 pcs -...

cgtrader

It has a full oral setup with teeth and tongue. The maya file does not have a shader network set up, only has basic colors with Lambert material applied. Preview images were rendered with Arnold (MtoA 3.2.0.2) Control Rig Description: The model is...

prusaprinters

I used seam painting for the gears to ensure that seams do not start on the teeth, springs or pallets of the anchor.Nearly everything needs to be strong, so I sliced with 3 perimeters, 6 bottom and top layers and 40% gyroid infill.PETG strings really...

thingiverse

[Top](#TOP) --- ## DIYLB Idler Assembly ### Vitamins |Qty|Description| |---:|:----------| |1| Nut M5 x 4mm | |1|...

prusaprinters

You're creating a shim, and it'll take about one square centimeter of aluminum. Put your hobbed gear on, with the working part of the teeth oriented toward the large gear. Be careful pushing it on, so as to keep the aluminum flat and even under...

thingiverse

--- The belt (regardless of which option you chose) can then be fed under the axle, over the two BeltSlide's (inside the small teeth that hold it), under the other axle, and back over the bed. --- ###### DIY Belt Coating You will want to tape...

thingiverse

Teeth that mechanically locks the parts together when pulled towards the body, but releases when pushed away.  ##TLDR Instructions ...

prusaprinters

I found that the vertical version runs more true as there is very little warping. You can also find some experimental parts here: https://www.thingiverse.com/thing:2921004/ Current experimental parts are: Knobbly Tires Spur & Pinion gears with...

prusaprinters

The belt teeth should be facing toward the bearing. Tighten the M4 screw and make sure the arm can still move freely.</p><figure class="image"><img...

thingiverse

It can be found here: https://www.thingiverse.com/thing:16627 Some basic settings are as folows: Teeth 172 Profile 12 shaft 18.3 m3 dia 3.6 hex 4 flats 6 depth 0 retainer 1 ht 1 idler 1 ht 1 pulley t ht 7 pulley b ht 10 pulley b dia 40 nuts 4 angle...

prusaprinters

After trying various pivot structures, we settled on a double rack-and-pinion derived from janssen86's Gear Rack and Pinion; the (rather tiny) gear core serves primarily to keep the pivot point from moving, while the herringbone pattern of the gear...

prusaprinters

Make sure the number on the Jaw Gear matches the one on top of the Align Tool. LUBRICATE: If you want your vise to really move smoothly, add a couple of drops of oil to the Jaw Gears Teeth before installing the scroll plate. I...

prusaprinters

May need to be printed slower because of curves and belt teeth. "Pins", print with brim because of height to diameter Some Hardware information:- The Drive Belt:- 76MXL025 95-Tooth 6.4mm Width Black Industrial Synchronous Timing Belt 7.6" eBay seller...

prusaprinters

Make sure belt teeth is pointing in the correct side, look at the pictures. SLIDE Y AXIS: Rectangular shapeInstall PULLEYS only on left side first. Notice that belts are on a different high. The taller PULLEY is closer to the KNOB on the...

thingiverse

The idea was to bring a superlight direct drive extruder to the SR by integrating it to the housing and getting the motor as low as possible above the effector plate Want a lighter setup, check my deported blowers system ;-)...

prusaprinters

BOM: 4 - M4x25mm screws 4 - M4 nuts 5 - M3 nuts - 4 inserted in Top_Part and 1 in pulley 8 - M3x8 SHCS - 4 for cage and 4 for stepper 1 - M3 set screw - pulley 4 - M3 washers - (optional) 1 - M5 washer - (optional) 1 - GT2 Timing Belt - L=158mm W=6mm...

prusaprinters

Added section on setting the time, note about assembly, and an external link to a sped-up gif of it running.Big Fix(2021-06-30 11:00-07) Took me too long to realize that the hours were just off, then took me ‘til now to realize that it’s because the...

myminifactory

As “luck” would have it, after years, a dwarven guerilla ship armed to the teeth with the heaviest cannons gold could buy, ambushed the convoy Samira escorted. The only warning shot that was fired tore through The Serenity’s rear, Samira’s quarters,...

prusaprinters

Be careful of course with the springs and wear eye protection when installing them. If you don't enjoy clickety click sounds, then now is a good time to install a rubber band on the geared teeth of the reel to quiet them down. Regular rubber bands...

prusaprinters

Car gearbox number of teethratio1st gear45-153:12nd gear40-202:13rd gear36-241,5:14th gear30-301:15th gear20-400.5:1reverse gear33-16-113:1NecessaryBeringsTo print this model you need 10 berings. You can use this <strong>old berings</strong>...

thingiverse

# Recommended print settings Gears: 0.10-0.12 mm layers, 3 walls, recommend reducing to 0.35 mm outer wall to allow a contiguous second wall in teeth. Use 5 walls for the no-bearings version of the planet gears to get a solid part. This is...

gambody

The car with Hammond's grandchildren stopped right next to the Tyrannosaur cage and this diorama captured that famous moment from this film.ABOUT THIS 3D MODELThe model is saved in STL files, a format supported by most 3D printers. FDM version...

prusaprinters

Make sure 5V PSU is always on when power is applied but the main PSU only is powered when the Raspberry Pi is turning it on via PSU control plug-in.Mount the top/large PSU cover by clipping it in to the cable rails and screwing it onClip in the...

gambody

The features of Shellder, the spiral shell who has its teeth sunk into plump Pokémon, are significantly emphasised when compared with the cartoon pearl-like character. 3D artist’s version of the creature has many spikes across the surface of the...

cults3d

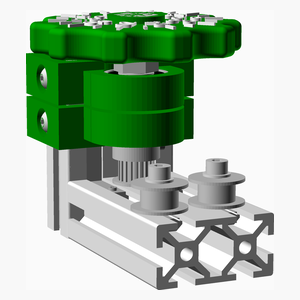

Furthermore you'll need a timing pulley GT2 20 teeth, an idler pulley with 20 teeth, a GT2 Belt 6mm / 380 mm in length, an M5 x 10 mm brass insert and a M5 x 30 mm screw. Update 15 Did some minor design changes on the parts S01c/S02c. So you may...

prusaprinters

The next task is to install them so they fit as pictured in the gearbox cover.To do this, I typically push in the handle connected to the main axel as far into the hole as I can and align the teeth of all the gears then slide them back into place...

prusaprinters

Shafts and nuts marked with “R” are normal right handed threads, shafts and nuts marked with “L” are left handed threads.All gears have their number of teeth in the name, so if you do not know which gear is which you can count the teeth.Gears 27-10,...

prusaprinters

The cranks on each side must be aligned so that both cranks on each leg are at the same angle, if they do not line up remove the small cog, rotate it by one or two teeth, and try again.Then continue with the other end. The crank positions must match...

thingiverse

FIX: Move the slider up and down a bunch, keeping the ratchet teeth disengaged. Tilt the sliding piece at a slight angle while doing this to smooth out the rough parts. It catches primarily when the piece is at a slight angle when being moved, keep...

prusaprinters

This needs to be removed after printing! The space between the teeth should be completely free!I have printed ALL parts with a brim. Especially the Body is suspect to warping due to many overhangs.Known Issues: can I fix my problem?Hammer stops half...