fursuit teeth 3d models

24947 3d models found related to fursuit teeth.

prusaprinters

I basically taped the acrylic to the back of the gloss paper and carefully cut both of them out at the same time with a scalpel.Important - The Ratchet Collar can be positioned in 2 ways but has an odd number of teeth.Therefore it is important to...

prusaprinters

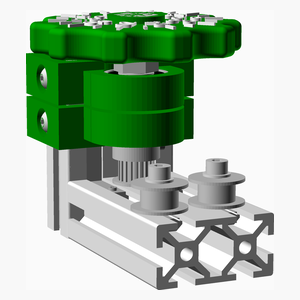

...Insert the M5 nylon lock nut on top of this. Note: The MK8 hobbed gear has very shallow teeth and not very sharp to avoid deforming the filament. In my case I have to apply a considerate amount of force to the tension sprint to avoid filament slip.

thingiverse

- Mount the top/large PSU cover by clipping it in to the cable rails and screwing it on - Clip in the mainboard cover and securely screw it down - Clip in the bottom/small PSU cover making sure the teeth properly fit into the large/top PSU cover to...

prusaprinters

The mount itself loops the belt over on itself, engage the teeth with each other, and pinching it while you run the bolt through the belt hole; similar to the original mount for the belts, but far more sturdy, and simpler to adjust the length of the...

prusaprinters

Make sure that the left support goes into the notch between the 2 "teeth" on the front panel. Connect the 2 ribbon cables to the LCD screen. Using the original screws and square nuts, mount the whole panel to the printer. Install the cable clips to...

prusaprinters

As the lever assembly rotates clockwise the pawls ride up the sloped gear teeth and the pawl springs compress, after the pawl slips off a tooth the spring pushes the pawl into the tooth base and then the pawl rides up the tooth face again. The...

prusaprinters

First, mesh the teeth of the main axle gear with the double gear, and push the metal threaded rod through the hole in the lower chassis and all the way through the main axle. Secure at both ends with washers and nuts from the filastruder kit. There...

prusaprinters

Be careful of course with the springs and wear eye protection when installing them. If you don't enjoy clickety click sounds, then now is a good time to install a rubber band on the geared teeth of the reel to quiet them down. Regular rubber bands...

prusaprinters

old ATX) 1x Fan 12V (for the laser) 2x Nema 17 stepper motor Mechanics 2x 8mm Rod, 370 mm (Y axis) 2x 8mm Rod, 330 mm (X axis) 8x LM8UU linear bearing 16x Ball bearing 625 ZZ 6x 5mm steel rod, 40 mm 2x GT2 Pulley, 20 teeth ca. 4m GT2 belt</li>...

thingiverse

Perform the bed mesh procedure and adjust the height by skipping teeth. <li>Repeat until the right rear corner is at the same level or up to one belt tooth higher than the other corners. <li>For each corner that's lower than the right rear, turn...

myminifactory

Sacrificing a part of their souls, they became Skinchangers — tempests of claws, teeth, and raw fury.Their unmatched ferocity was destined to be the stuff of legends, echoed in the tales sung by Skalds. Berserker SkinchangersWhen a berserker...

thingiverse

First, mesh the teeth of the main axle gear with the double gear, and push the metal threaded rod through the hole in the lower chassis and all the way through the main axle. Secure at both ends with washers and nuts from the filastruder kit. ...

prusaprinters

...If the teeth don't dive in, it's the wrong gear. Put the holder with the small-radius on top. Rotate the Big Gear until you find the hole in the holder aligned with the holes in the gear. Put the shaft into the assembly. Make sure holes still align.

myminifactory

In terms of mechanics and electronics, this design uses the cheap 1/10 scale ones.We could consider that the 3D printed gears would be 1/8, as they use Mod1 teeth size, normally related to 1/8 rc cars. So if you are looking for a sourced motor...

prusaprinters

This is why the carriers for the SFU1204 z nuts have that trunk looking part extending to the top. For XY I made a remix of yuris 9mm belt upgrade for the BLV mgn cube to fit 6mm belts and idlers. You might ask "why would you do that since the...

thingiverse

Tears, wailing, and gnashing of teeth will happen if you do! The steel will break if you wrap it around the small diameter of the bearings. I found this out the hard way in another build. Print List: Back Idler - normal and mirrored Y Idler v5 -...

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=53235 Instructions Using the following options: GENERIC_Crank_Generator = True gear_housing_diameter = 4 music_wheel_spokes_number = 35 pin_location_Y_axis = 13 case_snap_release_tolerance =...

thingiverse

The below videos show how the Saitek's Pro Flight Yoke functions after installing the 180 degree rotation mod: https://youtu.be/08HHLVGa9TE https://youtu.be/g-3My-s4lxg The timing belt must be GT2 type, 3mm wide, 2mm gap between teeth, preferably...

cgtrader

It has a full oral setup with teeth and tongue. The maya file does not have a shader network set up, only has basic colors with Lambert material applied. Preview images were rendered with Arnold (MtoA 3.2.0.2) Control Rig Description: The model is...

prusaprinters

Updated Klipper step_distance for 1000mm Bowden Tube. BOM: (may need some updating) 4 - M4x25mm screws 4 - M4 nuts 6 - M3 nuts - 7 - M3x8 SHCS - 3 for cage and 4 for stepper 1 to 3 - M3 set screw - pulley 4 - M3 washers - (optional) 1 - GT2 Timing...

prusaprinters

Those parts are also supplied without supports if you would rather use your slicers supports. Building the model Colors Skin: (Paramount3D PLA - Universal Beige) arm_right arm_left leg_right leg_left head OR head_with_supports .. Yellow:...

prusaprinters

I used seam painting for the gears to ensure that seams do not start on the teeth, springs or pallets of the anchor.Nearly everything needs to be strong, so I sliced with 3 perimeters, 6 bottom and top layers and 40% gyroid infill.PETG strings really...

thingiverse

[Top](#TOP) --- ## DIYLB Idler Assembly ### Vitamins |Qty|Description| |---:|:----------| |1| Nut M5 x 4mm | |1|...

prusaprinters

You're creating a shim, and it'll take about one square centimeter of aluminum. Put your hobbed gear on, with the working part of the teeth oriented toward the large gear. Be careful pushing it on, so as to keep the aluminum flat and even under...

thingiverse

--- The belt (regardless of which option you chose) can then be fed under the axle, over the two BeltSlide's (inside the small teeth that hold it), under the other axle, and back over the bed. --- ###### DIY Belt Coating You will want to tape...

prusaprinters

Make sure the number on the Jaw Gear matches the one on top of the Align Tool. LUBRICATE: If you want your vise to really move smoothly, add a couple of drops of oil to the Jaw Gears Teeth before installing the scroll plate. I...

thingiverse

It can be found here: https://www.thingiverse.com/thing:16627 Some basic settings are as folows: Teeth 172 Profile 12 shaft 18.3 m3 dia 3.6 hex 4 flats 6 depth 0 retainer 1 ht 1 idler 1 ht 1 pulley t ht 7 pulley b ht 10 pulley b dia 40 nuts 4 angle...

prusaprinters

Be careful of course with the springs and wear eye protection when installing them. If you don't enjoy clickety click sounds, then now is a good time to install a rubber band on the geared teeth of the reel to quiet them down. Regular rubber bands...

thingiverse

# Recommended print settings Gears: 0.10-0.12 mm layers, 3 walls, recommend reducing to 0.35 mm outer wall to allow a contiguous second wall in teeth. Use 5 walls for the no-bearings version of the planet gears to get a solid part. This is...

prusaprinters

After trying various pivot structures, we settled on a double rack-and-pinion derived from janssen86's Gear Rack and Pinion; the (rather tiny) gear core serves primarily to keep the pivot point from moving, while the herringbone pattern of the gear...