boosted pulleys 3d models

38681 3d models found related to boosted pulleys.

thingiverse

- 1x Roll of 6mm Belt (Amazon) - 8x 5mm bore/6mm Belt Idler Pulleys (Im not sure if you can reuse the new 2019 Tronxy idlers) Special Notes: - The Idler towers are tricky to bolt on into the frame. You need to take one screw off and install it after...

grabcad

The design of this ventilator is based on a large pneumatic cylinder driven by a motor via a belt and pulley system. The control software synthesizes sensor measurements and user inputs into a schedule that determines piston location and speed,...

prusaprinters

Here you could use external motor drivers.Video: https://youtu.be/scCJcUZJsKU Materials used (affiliate links):If you buy through these links, you support my work.Belt 240mm: https://amzn.to/3E4eB7I Hammerhead nuts:...

myminifactory

Part files:- 20_tooth_MXL_Motor_pulley.stlUSE_Hex_Bolt_Main_Body.stlUSE_Pins.stlUSE_Push_Plate_no_nut_needed.stlUSE_Thiner_Main_Belt_Drive.stl I do not recommend this print 20_tooth_MXL_Motor_pulley.stl a 20 Tooth belt pinion : Plastic model may...

cults3d

These 25mm screws are what Anet should have provided in the 1st place for proper pulley, rods and belt alignment. See image #3. Using the gauge the easy way. Updated 08/23/2018: Put the extruder in the Home position. Turn printer off and center the...

cults3d

This threw me a little because it was only occurring on the Y travel but of course in Core XY terms this is when both forward pulleys are rotating opposite to each other. Anyway I have since replaced the forward steel washers with nylon ones (M5 x 15...

thingiverse

Original collet and nut produce severe bit wobble, you need a Ryobi compatible collet nut (M14 -1) and collets, zip router collets work but the collet nut does not fit Don't mount with out the router without the Two 500gm coil springs and pulley...

prusaprinters

Assemble the idler pulley hardware. insert the 2 heat set inserts into the baseplate Bolt one of the 1/4" threaded spacers to the center-ish hole using one of the 6-32 bolts in the recess (after cleaning the hole) bolt the base plate to the idler...

prusaprinters

I used a smooth/wipeable melamine faced furniture board) 580mm x 450mm x 18mm, QTY 1A Spool of PETG ,QTY 1Some PLA ,QTY 1EiBotBoard, QTY 19V 1.5A AC/DC Power Supply Adapter 5.5mm x 2.1mmPen Holder, QTY 1Precision Hardened Steel Smooth Rods - 8mm,...

thingiverse

This threw me a little because it was only occurring on the Y travel but of course in Core XY terms this is when both forward pulleys are rotating opposite to each other. Anyway I have since replaced the forward steel washers with nylon ones (M5 x 15...

cults3d

Basic Coefficient = 7.7038 for HTD pulley 3M 16T;and of course a reset (reboot).The controller also remembers the last position before the machine is turned off. This happens every time the Z-axis shafts stop rotating after two and a half seconds. -...

thingiverse

second motor plate, belts, pulley, MGN15C carriage - Hotend: Select 1 or 2 hotends depending if you will be using single or double extrusion, as well as 12V or 24V versions. - Extruder 1 / 2: Leave Extruder 2 empty if you will be using single...

prusaprinters

old ATX) 1x Fan 12V (for the laser) 2x Nema 17 stepper motor Mechanics 2x 8mm Rod, 370 mm (Y axis) 2x 8mm Rod, 330 mm (X axis) 8x LM8UU linear bearing 16x Ball bearing 625 ZZ 6x 5mm steel rod, 40 mm 2x GT2 Pulley, 20 teeth ca. 4m GT2 belt</li>...

prusaprinters

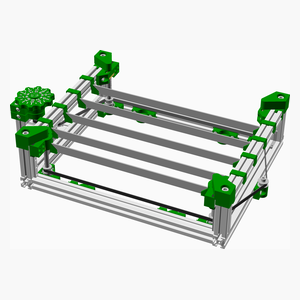

Here you can find the complete model in Fusion 360: https://a360.co/2rAbleL Used extrusions: 20x20 Aluminium Extrusions Black with corner cubes 7x 340mm (X Axis) 6x 320mm (Y Axis) 4x 400mm (Z Axis) 1x 220mm (X Bed) 2x 230mm (Y Bed) 8x Corner Cubes...

prusaprinters

With my brief Core XY experience I would consider this normal on the Y axis.Edit:23\01\21This was not a linear Rail issue, the noise was coming from the forward idler pulleys. This threw me a little because it was only occurring on the Y travel but...

thingiverse

There's a lot to say about this printer, but i'll try to be as concise as possible: The main design goals of this printer are: * very high print quality * easily enclosable * precise and smooth kinematics * fast (if you want to) * correct and sturdy...

thingiverse

A dab of super glue can help keep them in place) 2x M3 Nuts Mounting Z Axis with POM wheels 2x Bracket_Spacer.stl 3x M5 Washers 1x 2GT Open Synchronous Timing Belt 6mm Width, 1M Length You'll need around 67cm, I don't have an accurate...

cults3d

These 25mm screws are what Anet should have provided in the 1st place for proper pulley, rods and belt alignment. See image #3. Using the gauge the easy way. Updated 08/23/2018: Put the extruder in the Home position. Turn printer off and center the...

prusaprinters

Add 1 x M8 washer or 5/16" washer, one white spacer, the two halves that make up the idler pulley, add the second white spacer & then tighten everything down with a M8 locknut or 5/16" locknut. See the first picture for details.</li><li>Once all...

prusaprinters

Lasers work better with stickers. Mostly complete Bill of materials with links: A possible source for the lower crossbeam: http://www.ebay.com/itm/ORIGINAL-STEELCASE-Front-To-Back-Rail-Kit-f-Lateral-Files-ONE-PAIR-BLACK-/121894212251 The M5 heat set...

thingiverse

Level the bed by turning the thraded rods, before tightening the pulleys  [Top](#TOP) --- Finished! ... <span></span> ...

thingiverse

Kentucky Saints Four fans are the unsung heroes of the team, providing a boost of energy and enthusiasm at every game. They're the ones who paint the town in Saints colors, who chant the team's name from the rafters, and who cheer on their favorite...

prusaprinters

That is not something I need, or is currently able to do.Lithium Charger\Boost ConvertereBay Search: lithium charger boostThese are 2 in 1 boards. One side has a lithium battery charger, and the other has a boost\step-up converter. The charger side...

prusaprinters

...Solder the negative input of the boost converter to the negative output of the charging board, and solder the positive input of the boost converter to the other side of the switch. If not using a boost converter, just leave two long lengths of wire.

cults3d

Attach the belt to the belt clip in the upper half of the printed carriage, then run it up and over the idler pulley at the endstop holder, then back down through the left side of the carriage, around the motor pulley, then back to the printed...

thingiverse

The T8-2 threaded rods (single thread start) used provide a 4:1 ratio increase over T8-8 threaded rods (four thread start) and provides more than enough resistance to prevent any build plate sag when the steppers are off so larger pulleys for the...

prusaprinters

;******* 3D UnderClippy Code ******** M906 X1060 ; Boost Stepper Current ; cut off filament tip G0 X-30 F5000 ; Cut the filament quickly G0 X30 F5000 ; Move X back to position M906 X580 ; Restore Stepper Current ; ******* End UnderClippy Code ; we...

prusaprinters

It's about 320mm cubed (1ft cubed). It's using 210mm, 230mm and 250mm 2020 Series Aluminum Extrusion but should be able to scale to anything (I think), you would just need to alter the Marlin configuration files and get longer rods, belts and a...

thingiverse

AC Motor" /> <a href="https://www.thingiverse.com/thing:3158065" title="Stand Press. 2 in 1"><img src="https://like-it.link/0234/Stand-Press.jpg" alt="Stand Press. 2 in 1" /></a> <a href="https://www.thingiverse.com/thing:3139427"...

thingiverse

AC Motor" /> <a href="https://www.thingiverse.com/thing:3158065" title="Stand Press. 2 in 1"><img src="https://like-it.link/0234/Stand-Press.jpg" alt="Stand Press. 2 in 1" /></a> <a href="https://www.thingiverse.com/thing:3139427"...