bed scraper 3d models

122464 3d models found related to bed scraper.

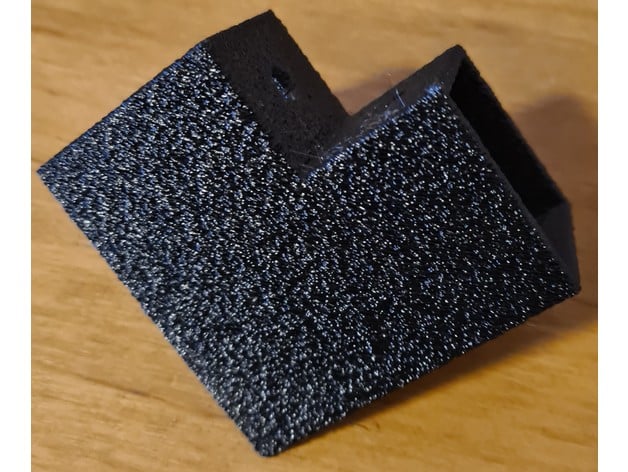

thingiverse

Since I have a textured print bed this fits perfectly together  After all parts are printed and the wood is cut to length and...

prusaprinters

The long rectengular shape in the middle could get support because it is easy to take off. The Base part should get around 100°C (I used PLA) or even higher bed temperature to avoid the Warping effect. Turbine blade: Infill: 100% Layer hight 0.1mm...

thingiverse

... flashing, you still have to load the standard values with "M502" and save with "M500". Calibrate extruder, perform PID tuning, bed leveling, be happy :-D I hope I haven't forgotten anything and it will help you with your renovation! ...

cults3d

It was the bed height. The hotend tip on the AB toolhead is much higher than the stock hotend, which makes the X carriage having to be much lower than before. It almost hit the bottom limit - actually the X carriage end hit the Z stepper mount bar...

prusaprinters

To get stronger spokes you can print them laying flat on the bed but this requires supports. Also the friction fit changes when printing parts in different orientations.</p><h4>Infill</h4><p>The hub isn't critical, I usually print it with 13 %. Note:...

prusaprinters

Last step is to divide it up to fit on your print bed and cut-out pin recesses.I print from there, and as i assemble, I tweak my model as needed to make it better for then next person who prints.Its good to remember that plastic is melt-able and easy...

prusaprinters

For that just move the vase down into the print bed inside the slicer until only the top edge is printed.Since vase mode does not support top layers I chamfered/sloped the upper edge in a way that the spiraling perimeters eventually meet and overlap...

prusaprinters

This took me something like 50 hours of printing time and 150 meters of filament (with 9 full printer beds of stuff!), so it's not exactly a small project... but I'm pretty happy with how it came together! This insert is designed to replace the...

prusaprinters

It was the bed height. The hotend tip on the AB toolhead is much higher than the stock hotend, which makes the X carriage having to be much lower than before. It almost hit the bottom limit - actually the X carriage end hit the Z stepper mount bar...

prusaprinters

If you wish, it's also a good time to paint the bird logo as I did.The Budgie parts need to be assembled for use, but it's pretty simple:Put the E and M parts together with the sides that were on the bed facing each other. Push the top and bottom...

cults3d

Parts 2 - Closet door hardware 1 - Boroscope camera (https://www.amazon.com/dp/B071HYRPND/ref=cm_sw_r_apan_glt_fabc_N0M3MJPRH2NBZRRFNEY8?_encoding=UTF8&psc=1) 2 - Soil moisture sensor...

prusaprinters

Please also note, I have added some "attachment supports" to the wipe tower and some parts in order to make them attach more firmly to the print bed (you don't want them to come loose after 24 hours of print). This lamp was designed using blender,...

cults3d

I printed with a 1mm brim to help them stick to the bed, then used a hobby knife to cut the brim off. I used PETG, but I suspect anything would work well enough. For the wheel nuts Dude, I don't know how I managed to successfully print these. They...

prusaprinters

Since it is a large print, please make sure you have good bed adhesion or it will warp. The smooth steel sheet worked great. The other advantage of using the smooth sheet is that it makes the front of the TV look better. While I love the look of...

prusaprinters

Post-Printing In addition to the supports added by your slicer, the gear box has a ring and a set of little vanes about a centimeter tall at the bottom end, just there for the purposes of bed adhesion. Cut them off if so desired - they shouldn't get...

prusaprinters

FeaturesModular structure, easily scalable, put modules together, twist & lock, doneFilling module with cap3-way planting modules (hollow version recommended)Internal/external water dispenser modulesLidCustom net pot for Jiffy-7 41 mm grow medium...

prusaprinters

The head pole piece prints directly on the printer bed, so should always be smooth. The pole and equator sections need to be glued together. UHU All Purpose adhesive works very well for PLA, but the pieces should be clamped or taped in place while it...

prusaprinters

It's worth noting that there is 0% infill until 11mm off the bed.There are 2 facet types AAB and BBB - A and B being the 2 edge lengths. So AAB is a triangle with A, A and B length sides.</p><p>FullHalfAABMagnets.3mf is one complete half...

prusaprinters

If you want, you can print two of these and put them on both sides of the frame.Nema 17 stepper motor adapter (orange, below the frame) for advancing the film with a stepper motor.Lens attachment (cyan) for setting the right focus distance (beige),...

prusaprinters

Rotate the parts by 45 degrees to fit on the Prusa Mini bed. Make sure to place the Z-Seam on the side that faces down after assemblyI got some pretty bad warping on the housing and had the Z-Seam on the top side but I decided to use it anyways for...

prusaprinters

The height of the main area of the coaster is 6 mm, with the total height being 7 mm to the top of the rim.You can fit two coaster bases onto the bed of a Prusa Mini! Coaster PartsEach coaster has 4 parts that need to be printed:BaseBeauty...

prusaprinters

My back piece was a bit flimsy so I needed to print some cylinders with screws going from the top all the way thru to make it sturdier. Place the camera towards the top and in the middle of the bed and mark the four mounting holes. Use a 3.2 mm...

prusaprinters

The top magnets have since been moved closer to the hinge for better springiness during clip actuation. Step 3: Press the magnets all the way into their pockets until the tops are flush with the top surface of the print, then resume the...

gambody

Material shrinkage does not affect at strength and friction.STL files with new scale and new joints are already available for download in “Source files” tab for:- Version 2 - STL files on FDM/FFF 3D printers;- Version 3 - STL files on DLP/SLA/SLS 3D...

thingiverse

For example, we split the thrust chamber into rings so that it would print without supports * For thrust chamber ring 1, make sure to turn off skirt loops in print settings so it will fit on the print bed. 2. Begin gluing thrust chamber sections...

thingiverse

([PR #2844](https://github.com/bigtreetech/BIGTREETECH-TouchScreenFirmware/pull/2844)) - reworked the buzzer handler, it is purely interrupt based with the benefit of more consistent sound patterns and no interference with other tasks ([PR...

thingiverse

The bed was far back from the windows, and I sat with the windows open and undressed by the bed. Outside a night train, running on the street-car tracks, went by carrying vegetables to the markets. They were noisy at night when you could not sleep. I...

prusaprinters

Take what's theirs and make it your own! ~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~More fun stuff:Construction:Building under construction Part 1...

prusaprinters

On one board both the ABL header pins and three pin pancake stepper motor (Sherpa mini) run alongside the heated bed and hot-end heater cartridge wires. My bed heater is 200W at 24V so draws up to 8.4A.My intention is to minimise the hole needed to...

gambody

Each part that any model comprises often needs preliminary review and you are free to tweak the settings the way you find suitable.Note:- You can scale up the model (downscaling is not recommended!);- All connectors should be printed at 100% Infill;-...