automatic assembly machine 3d models

352964 3d models found related to automatic assembly machine.

cults3d

First step: assembly. The order and placement of the pieces are sufficiently explicit in the images in this post. All cards except the USB charger can be placed in the "boards.stl" part. Second step: programming. Make the servo drivers or look for...

prusaprinters

Three RNA molecules will be used to assemble the protein: Messenger RNA, Transfer RNA and Ribosomal RNA. Messenger RNA (mRNA) has the information for arranging the amino acids in the correct order to make a functional protein. Transfer RNA (tRNA)...

grabcad

The housing is specially designed to dissipate heat which increases the efficiency and lifespan of the LEDs and electronics.The entire assembly is ETL listed Class I Divisions 1 & 2 and Class II Divisions 1 & 2 for use in hazardous locations...

prusaprinters

x 10mm Long Compression Spring: https://www.amazon.com/gp/product/B01N6RMGD2/ref=oh_aui_detailpage_o00_s03?ie=UTF8&psc=1 2 - PTFE fittings -...

thingiverse

Assembly ------ Please use this diagram as a reference:  **Note**: It should not be necessary to use...

prusaprinters

The original design is really cool and I remixed it to open/close quickly using multi-start threads.A big thank you to LAY3RWORKS for the great original design which was the inspiration for this model.Print SettingsPrinter Brand: PrusaPrinter: I3...

grabcad

Fixture arrives assembled and lamped to reduce installation time and cost.3. Fixture constructed of extruded corrosion resistant copper free aluminum alloy4. No ballast box. No ballast to replace.5. Heavy gauge extruded aluminum reflectors with high...

thingiverse

(don't worry about resizing the spacers, they will probably be fine) KlbdMidTest & KlbdEndTest - These test prints are for checking the fit of the dovetail used to assemble the keel board pieces. Make sure the KlbdMidTest part is printed in the...

thingiverse

This is important to consider because this space is significantly more narrow than the inside of the rest of the helmet and will result in more open space within the helmet after assembly if scaled relative to the leather parts. This means you will...

prusaprinters

Assembly Please have a look at the attached images before mounting the lamp, it is much easier than just reading this text. Especially, the lamp shade parts can be "zip locked" together easily, then locked into place by the square lock piece which...

thingiverse

The individual sections can be printed at once, this will also speed up the assembly process. 5/10/2023 - Due to popular demand. Smaller version added. The main body is 211.95mm x 190.32mm. The chess and checker pieces remained the same size. ...

prusaprinters

Not sure if my print warped or if it's a little bit off.Hardware:(4x) M4x12 screws (adapter plate to gantry - original M4's on the SV01 extruder probably aren't long enough)(4x) M3 heat set threaded inserts(4x) M3x20 screws (shroud to adapter...

thingiverse

As for the instructions of putting everything together, I never actually filmed the assembly process, but I will include the original Fusion 360 file so that you can see how everything fits together and so you can change the design however you want...

thingiverse

You may need to file the edges a bit to account for elephant foot, but it is a tight fit regardless, so don't be afraid to use a bit of force during assembly. Also, while I recommend printing the joints with PETG or ABS, I have only printed these...

grabcad

The housing is specially designed to dissipate heat which increases the efficiency and lifespan of the LEDs and electronics.The entire assembly is ETL listed Class 1, Divisions 1-2 and Class 2, Divisions 1-2 for use in hazardous locations and...

grabcad

Cuts were created where possible to both simplify parts, and give them a sharp nice looking profile, and the part separation was done in such a way to allow for a tri-chromatic pattern to nicely underline the tone of the tool.Please find below linked...

thingiverse

- [merchantman-blender-files.zip](https://drive.google.com/file/d/1XYkN_XtefVgIEPelLYKaxvLams7DHjgP/view?usp=sharing) – Contains the source blender files used to generate the parts, as well as files with the parts assembled as used to generate the...

prusaprinters

... Start by placing the knob in its assembled position in the pivot part, underneath the 2 retaining lips. Then insert the ¼-20 bolt into the knob and up through the hole in the pivot. The head of the bolt should press into the hex socket in the knob.

prusaprinters

The only thing that i couldn't get to work was the UV Lights since there are no addressable leds out yet so unfortunately i used the classic RGB leds to illuminate the DNA sculpture and only at the bottom for easier assembly. The project comes with a...

thingiverse

The intent of these additional files is to allow you to assembly and modify these parts to kitbash your own ship designs, without needing to build a model from scratch. ...

prusaprinters

I assembled these steps based on the guides i followed.1. Connect the PiTFT to the Pi</p><p>2. Install and Configure OctoPi. Follow the instructions form the <a href="https://github.com/guysoft/OctoPi">OctoPi website</a></p><blockquote><p>You might...

prusaprinters

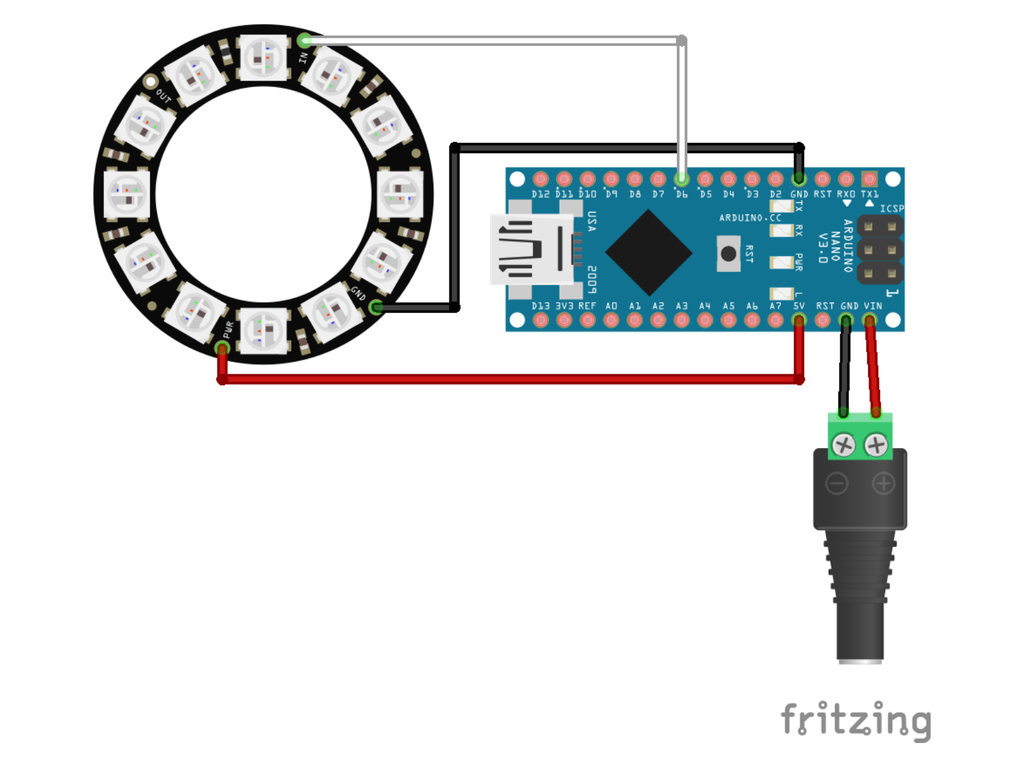

The steps will be similar for other operating systems. Remember to select 'Arduino Nano' under 'Tools > Board'. Assembly Please use this diagram as a reference: Note: It should not be necessary to use a resistor or capacitor, however, they may be...

thingiverse

The lenses, shutters, and electronics all come out as one big assembly, which is nice. I actually removed everything except the film advance mechanism, and part of the reason for that was that removing the shutter release allowed me to advance the...

prusaprinters

You can use any printed feet or use my hyperfeetAssembly instructionsPrint all the partsInsert fans into printed fan shroudsClip in the fan shrouds to the top/large PSU cover and the mainboard coverOptionally insert cable clips into square-slotsMount...

thingiverse

### Post-Printing and Assembly The pump case has a 6.7 mm hole at the bottom. Most little DC motors have a little edge which fits there perfectly. The impeller itself supports a 2 mm motor shaft, however, you have to file one side of the shaft flat...

thingiverse

The 3mm hole patterns on the mirrored brackets, when assembled to the base of the Saturn, should match up with the hole pattern on the tabs of the manifold. If you are using the mcmaster-carr 2.5" exhaust hose like I did in the photos, also print the...

thingiverse

PRINTING and ASSEMBLY. This should be a simple print. You will notice that the body has a 1 mm cover on one side. This is to give it more stability and make it easier to print and remove from the printer. No support or attachments needed. Print in...

prusaprinters

You might want to print the part a little slower than usual because it's so tiny.Material: Use a material with great layer adhesion.Supports: NoLayer height: 0.2mm or 0.1mmExtrusion width: 0.4mmPerimeters: 3Infill: 0% (doesn't matter)Solid layers: 5...

prusaprinters

I used this one: https://www.ebay.com/itm/3-8-Carbide-Endmill-4-Flute-Flat-Bottom-Regular-TiAlN/133414909772?ssPageName=STRK%3AMEBIDX%3AIT&_trksid=p2057872.m2749.l2649SAE Size 016 O-Ring for each bushing - you can probably pick these up at any...

thingiverse

# Assembly Instructions ## Hemera Mounting Instructions * Press nuts into appropriate slots in backplate * You can use a bolt to pull them in. a clamp, any hard surface, or an arbor press. * They should be tight enough that they don't fall...