anet a8 mainboard schematic 3d models

28547 3d models found related to anet a8 mainboard schematic.

thingiverse

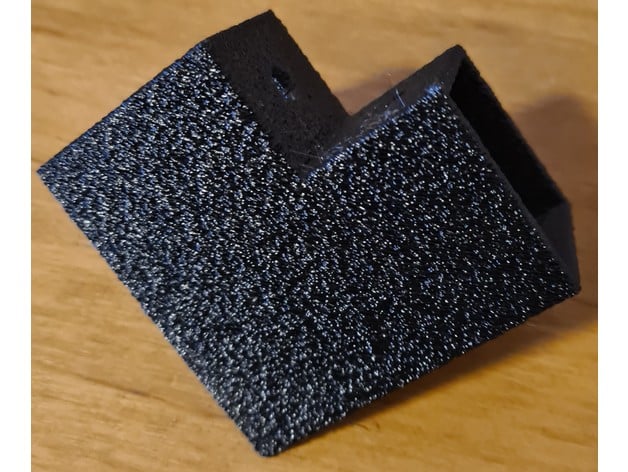

Printer: Anet A6 Rafts: No Supports: Yes Resolution: 0.15 Infill: 25 Notes: Printed using ABS: 0.3mm nozzle, 0.15mm layer, 110C heat bed @260C. ...The slicer is calibrated to provide 1:1 dimensions and no excess thickness (that is 2mm wall width in...

cults3d

These 25mm screws are what Anet should have provided in the 1st place for proper pulley, rods and belt alignment. See image #3. Using the gauge the easy way. Updated 08/23/2018: Put the extruder in the Home position. Turn printer off and center the...

cults3d

These 25mm screws are what Anet should have provided in the 1st place for proper pulley, rods and belt alignment. See image #3. Using the gauge the easy way. Updated 08/23/2018: Put the extruder in the Home position. Turn printer off and center the...

prusaprinters

The fan is placed so that it evacuates the case just like in the original design.There is also a small spacer for the fan because I only had M4x30 screws and they were about 5mm too long and were going to hit the mainboard. If there are M4x25mm...

prusaprinters

It doesn't particularly matter what convention you use, but for the record, I marked the edge that is leftmost if you are looking down at the mainboard, such that the edge with all the connectors on it is at the top. I hooked the wire from this edge...

prusaprinters

DO ADJUST E1 VRef on the mainboard to have the proper current for the new extruder stepper. The stock Creality stepper was 1.5A, for instance, my 23mm stepper is 1A, I tuned the VRef E1 voltage down to 0.8V. (how-to reference:...

prusaprinters

Wiring: If the fan wires do not match the socket on the mainboard PCB, either cut and re-solder the original cable -or - use a 2.5mm crimping tool and modify the fan cables to fit the socket. Using the M3 nuts... Use 4 of the M3 nuts with M3x15...

cults3d

DO ADJUST E1 VRef on the mainboard to have the proper current for the new extruder stepper. The stock Creality stepper was 1.5A, for instance, my 23mm stepper is 1A, I tuned the VRef E1 voltage down to 0.8V. (how-to reference:...

prusaprinters

https://newdimension.company.site/Before we begin, I'd like to thank ktothestank for his 250mm Bridge Test Model which I used in these tests. Slicer: Cura 5.1.0Resolution: 0.2mmNozzle: 0.6mmPrinter: Creality Ender 3 ProModifications: Creality...

prusaprinters

DescriptionThis SherpaMicro extruder and carriage setup weighs 50% less than the stock Qidi extruder/carriage resulting in better print quality.The associated linear rail gantry files can be found here:...

prusaprinters

Sorry for any confusion.Note: in addition to this revision, there are now three other editions of this:One that accommodates non-E3 TFTs (but only looks right while facing toward the X axis): LowRider 3 CNC - control box case for BTT SKR Pro 1.2...

prusaprinters

At the moment there is no designed feature in order to keep it firmly in place (because of its short length) but a piece of tape or a drop of glue should do the job if it falls outPart 5: MARRIAGEPlace the whole extruder assembly on the printer and...

prusaprinters

DO ADJUST E1 VRef on the mainboard to have the proper current for the new extruder stepper. The stock Creality stepper was 1.5A, for instance, my 23mm stepper is 1A, I tuned the VRef E1 voltage down to 0.8V. (how-to reference: <a...

prusaprinters

If a WiFi modue installed: TFT35-E3_Back_rev3_wifi.stl or TFT35-E3_Back_rev3_wifi_410mm.stl.TFT35-E3_Rear_rev2.stl or TFT35-E3_Rear_rev3_410mm.stlTFT35-E3_Mount_rev2.stl or TFT35-E3_Mount_rev3_410mm.stlButtons are unchanged:...

thingiverse

Since I have a textured print bed this fits perfectly together  After all parts are printed and the wood is cut to length and...

prusaprinters

Turn off the power and disconnect the power supply after the output voltage is set to around 5V.Add 2 red and 3 black wires to the output +/- contacts of the “DC-DC step down board”.One pair of red/black wires need to be connected to the “ESP” to the...

thingiverse

See the schematic, below, and the BISS0001 datasheet for details.On timeThe length of time that the output is on after being triggered is set by C1 and R2. The on time (in seconds) is roughly 24576 × R2 × C1. The default is about 30 seconds. To...

thingiverse

There is a schematic image included, but it depicts both parts top-side up so you'll need to adjust accordingly. Before doing any wiring first test fit the radio module, nano, and led ring into the base and get familiar with it. The base has wire...

prusaprinters

Refer to the schematic for more information. 11/16/19 Changed screw lengths to minimize stripping screws. Posted new zip file (Thingiverse files 110519.zip) that includes updates to the following STL files: L2 Lower Body L2 Lower Body Trellis2 Base...

thingiverse

Literatur: -Filtering routine (does not work ok) https://tttapa.github.io/Arduino-Filters/Doxygen/d3/dbe/1_8FilteredAnalog_8ino-example.html -Precise mearuring using external reference sources...

prusaprinters

You can see the texture in good lighting in one of the pictures on the floor. Electronics Connect all the parts as in the schematic picture. The battery slots have a 2perimeter (@ 0.4mm) arc that serves as a spring. It does have 2 holes to thread...

myminifactory

For the wiring, look for schematics.pdf Here is the arduino code: /* Jacques favre:drive 2 stepper motors to power a clock using a RTC for acuracy2 buttons to adjust time1 button: move secondsother button: move hours and minutes2 buttons: move...

thingiverse

I don't have exact wiring schematics, but I will explain what ever part does and how they interact with each other. First, you should start by wiring the three 18650 batteries into a pack. Use the female T-plug and male 3S JST connector for this. Now...

prusaprinters

I originally intended to use the coupler directly on the servo but I didn't quite work, it's much better to use the provided adapter which has teeth to match the servo's gear teeth.I taped the LED and LDR to the lid with duct tape and did the wiring...

prusaprinters

Refer to the schematic in the pictures. X carriageOn the original build the laser driver was fastened with regular M3 hex nuts you placed into the X carriage. I found this quite frustrating at time since they move around and potentially twist. In the...

prusaprinters

But it's well designed based on real dimensions of the parts used in the projects for maximum compatibility. Hardware requirements: Wemos D1 Mini v3 (https://www.aliexpress.com/item/32529101036.html). WS2812B 32led Ring...

prusaprinters

The screws of the top matrix are switched 180° to avoid electric shorts between the TOP, FRONT and BACK matrix! Code:The code can be found on my GitHub repository. ⚠ Important notes: ⚠ The provided code limits the amount of...

cults3d

There is a schematic image included, but it depicts both parts top-side up so you'll need to adjust accordingly. Before doing any wiring first test fit the radio module, nano, and led ring into the base and get familiar with it. The base has wire...

thingiverse

I initially hooked it up behind the one switch but there are times i want the lights on when the heater is not so I decided to add this feature Edit 1/8/2022: I've added wiring schematics and pictures of my final product. So this has been a long...

cults3d

#Note on Anet screens: They will not work with this board. Anet screens are not wired to the regular standard and are 5v. These use 3.3v logic. Use a 12864 or 2004 RepRap type screen. That said, Let's dive in! #Requirements SKR 1.3 Board ...