aegis defense line 3d models

170750 3d models found related to aegis defense line.

prusaprinters

These pins force the parts into alignment and ensure your pulley bearings are lined up straight.They are a tight fit and you will need to use force to install them. Use a drift pin of some type if you need to remove them. Do not try and pry the parts...

prusaprinters

Record the sequence on the line below. mRNA Sequence: Record the number on the back of the mRNA: On the Ribosome The A, P, and E sites are labeled. In the space below, describe what happens at each stage: Initiation: Slide your mRNA into the small...

prusaprinters

I used this to get my (currently) world record bedslinger #speedboatrace benchy at only 4m 48s.After trying other people's designs and having issues or bad performance as they always lacked something or another, I finally decided to design my own X...

prusaprinters

The robot has a ponderous gait. PrintingGenerally I use a 0.25mm layer height and put about 1mm of plastic on the outside surfaces as a shell. Since my printer has a 0.5mm nozzle I use 2 vertical shells and 4 horizontal top and...

prusaprinters

By continuing smoothing for a couple more times, the remaining layer line artifacts should completely vanish. A bit of over-extrusion might help, too.</p><p>If you look from the other side, you can perhaps guess that the smoothed PVB acts as some...

prusaprinters

If not then you will need to add some nuts to the back to hold the screws into place. When you mount this to the heat sink it is EXTREMELY important to position it so the cooling vent is lined up vertically. Otherwise you will suffer from more heat...

prusaprinters

I am not responsible for any injuries sustained while using this design. Notes on my accelerated printing settings: I have my printer's stock hardware (with 0.4 nozzle) using tweaked slicer settings that not only emulate a 0.6 nozzle, but also...

thingiverse

That is, make sure that the lengths, widths, and heights that you decide on are the same, so that the shapes will line up in the end. 15. Rotate the imported side view to be the correct orientation 16. Extrude both shapes in the required direction...

thingiverse

So this is the most troublesome to use, but if you have errors, try to:set a different (lower) bend angleset a larger bend radius, or try to reduce the error-inducing fillets radii, or eventry deleting unnecessary fillets from the time line...

cults3d

In this case, you won't need the "line-changer actuator" in the car but you will need electronics under each lane-changer track part, specially the "sensors" and the "actuator". There is a very good thing about the InfraRed lane-changers... You can...

thingiverse

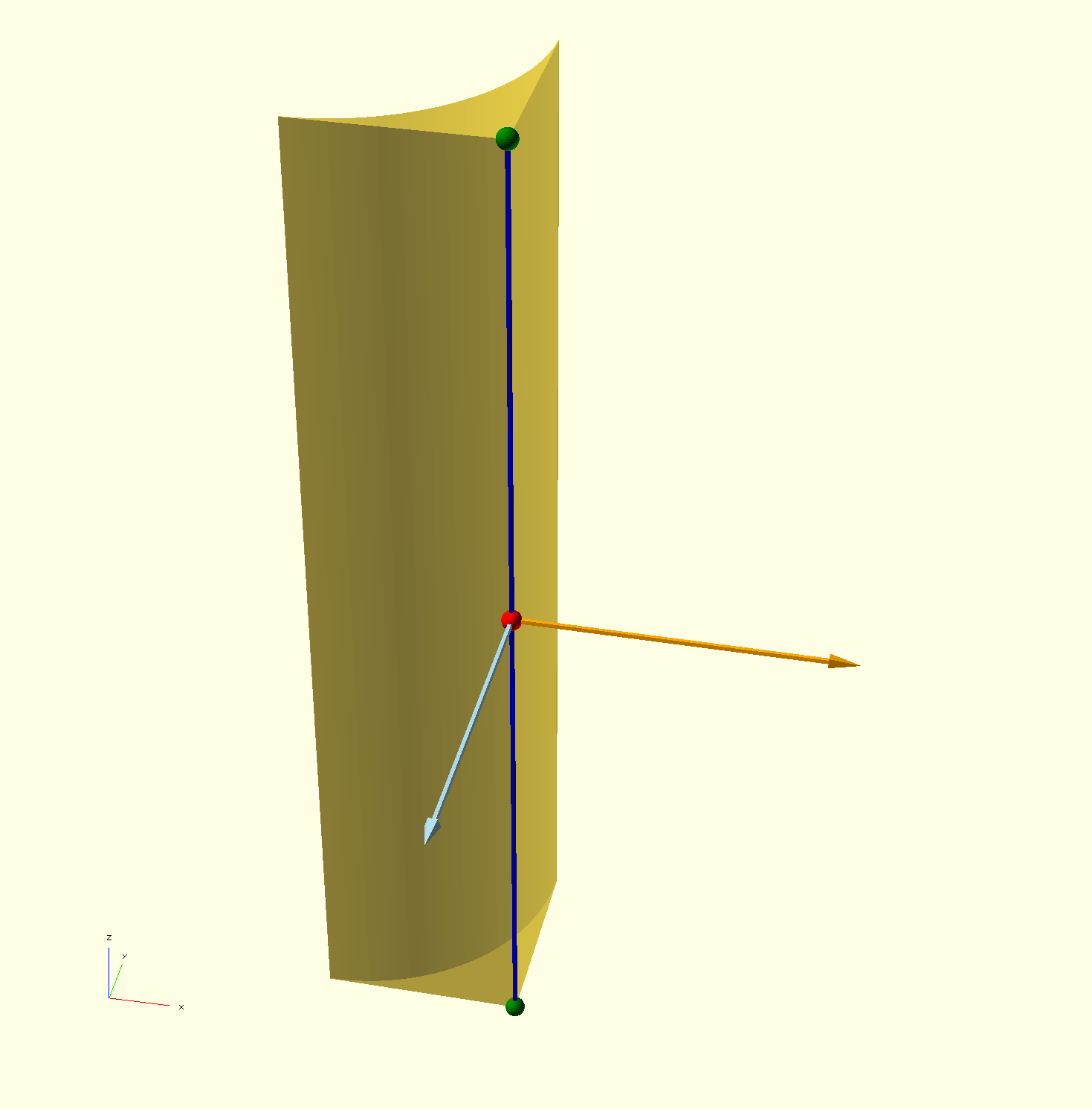

In the above image: - The blue line is the edge (corner) that you want to smooth, where the two faces meet. - The <span...

prusaprinters

Which is unfortunate, because adding that extra 20º really makes a big difference in how strong the PETG print turns out.) With thinner walls, you will also want to be sure to choose a very opaque color.There are a couple variations on the lid to...

prusaprinters

The line pattern on the yellow container was Designed by Freepik. The triangular pattern was remixed from a design by <a href="https://www.freepik.com/freepik">rawpixel.com / Freepik</a>. The floral pattern was remixed from a design by <a...

prusaprinters

We don't want to be gentle. Along the same lines, we don't want the 2nd bump to be too gentle. I increased the bump divisor from #define HOMING_BUMP_DIVISOR {2, 2, 4} to #define HOMING_BUMP_DIVISOR {2, 2, 1}.</li> </ul> <p>Then, in the start GCODE I...

prusaprinters

(after 4 weeks into this project) ### More information http://edutechwiki.unige.ch/en/Lego-compatible\_thesis\_project\_board Since this is my first project in line with my work, I may provide (over time) a more serious documentation in my wiki. It...

thingiverse

4.3 Slide in your 2020x frame with the linear rail facing your printer bed on both sides.(If your linear rail is only flush on one side, make sure the flush side is upwards near the XY axis) Make sure that you also slide in the Z lead screw braket...

prusaprinters

Others use 2 line lasers to form a cross at the spindle position, these are large permanent devices added to your spindle mount but are always there, just a flick of a switch away from seeing the spindle's position.My other thing, Z-Axis Pointer is a...

prusaprinters

Special considerations were taken due to 3D prints having layer lines and different directional strengths compared to other manufacturing process. What works for metal with traditional manufacturing methods does not work with 3D printing most of the...

prusaprinters

If you do not want to do the SpannerHand's mods, this will work with an uncut X cart and you should still be able to use the Z sensor as normal, HOWEVER the part cooling fan may not line up. This will be the same for an E3D v6 and UBIS hot end mount,...

prusaprinters

Print “Ikea_Lack_Hinge_V4_UpperLowerTableMiddle_Print4” four times, all other parts are needed only once.Also get 4 felt gliders to avoid a hard “bang” when you close the table.You also need 6 small screws (which fit into 3mm screw holes, just to...

prusaprinters

The two main parts were at 1 perimeter at 0.6 mm line width, 5 % infill and the two fan adapters with maxed out parameters, i.e. 100% infill. (With a 0.4 mm nozzle one would likely want to do 2 perimeters for a 0.8 mm hull width. ) Even with these...

thingiverse

This will be to tie a length of Kevlar line that goes to the parachute and nose shock cord. Bore the hole as close to the top ring as possible. 2mm or 3mm max. I have started putting a drop of CA on all Kevlar knots - I had two unravel on the same...

thingiverse

I'm going to redesign it because I made this to bolt to the factory mounts for the Qidi mainboard and line up with the side opening on that printer. My intention was to have the Lerdge connections be accessible from the side like the factory and so I...

prusaprinters

To achieve the best effect, use a large nozzle with large layer height and line width. The hair is the most difficult to print. If you want a nice surface you need to print it in the orientation as it is designed, but that requires a lot of supports....

thingiverse

Run the sensor and power lines through the wire channel. 8. Position the LED ring into the base and solder the data, VCC, and two ground wires. 9. Put a zip-tie around the power and sensor wires so that tugging on them won's put strain on the...

thingiverse

As usual, scope creep set in and the design expanded to include:A component to support round hygrometers which I think look better but also fit neatly between the dry box mold lines, making them easy to read. They are also ridiculously cheap in...

prusaprinters

The pin should be fully inside the hinge.Repeat for the second hinge.HaspPin the hasp parts together – do this before attaching it to the chest.Align the top plate and the flap of the hinge so that the hinge holes line up.Insert a pin following the...

cults3d

It was not so easy to insert the multi-wall sheet glasses so that the lines were exactly vertical. After I finally succeeded, I pushed in the glass fixing ring. It sits very tightly. That is the intention. This is additionally fixed with a little...

grabcad

We also offer a low voltage version of this LED fixture that operates on AC/DC voltages from 11-25 Volts and in-line step-down transformers for high voltage to low voltage operations.This explosion proof LED light fixture is IP67 rated, dust-proof,...

prusaprinters

Use 5 M3*10 screws. OK, we enter the finish line, slowly... Mount the 4th servo to the "left" part. Axis point to the front, but downwards. Connect OK fingers and "assholearm" together using another M3*10 screw. Mount the whole arm to the servo. DO...