1s toothpick frame 3d models

126477 3d models found related to 1s toothpick frame.

thingiverse

- The frame has been extended up, by 10mm - A groove/handle was added in the front. - The Top part has been changed, so that the window panel, will be mounted/glued, from the indside. This makes it print without supports, and gives a better...

thingiverse

The rescaled version is then loaded to Fusion360, where the base profile is extruded in negative direction -0.6 mm and the white parts inlcuding the frame are extruded to the positive direction +0.6 mm. Lastly I added colors to the faces of the sign...

thingiverse

I advise grounding the CNC frame to trigger the fuse instead of your body. FINAL UPDATE 1/31/2020: TLDR; Don't make this, instead make -> https://www.thingiverse.com/thing:4198567 Sometimes it's more important to admit when you did something that...

cults3d

It was a thrilling 24-hour event where we created something 3D printed that benefited social justice - and although we didn't quite finish within the given time frame, we still managed to secure second place. The actual development process took up...

prusaprinters

Please note when scaling down you will loose detail , if this is the case, resize the svg (or bitmap before converting.[logo position x] and [logo position y] You can adjust the x and y position with the respective position sliders. The logo extrudes...

thingiverse

On a proper 3M mask, the inside surface of the filter's mounting hub squeezes a rubber lip against the hard plastic frame of the bayonet assembly. We merely tighten the hard plastic filter mounting hub against the printed (hard) top rim of the...

prusaprinters

The rescaled version is then loaded to Fusion360, where the base profile is extruded in negative direction -0.6 mm and the white parts inlcuding the frame are extruded to the positive direction +0.6 mm. Lastly I added colors to the faces of the sign...

prusaprinters

Assembling the frame After you have soldered the leds, solder wires to the 5V, GND and D4 pin. Afterwards push the wires through the hole of the stock and solder them onto the starting led strip piece. Next attach the 2x M3 bolts with 1x M3 nut each...

prusaprinters

You may need a hammer or grips to help wiggle it off.Push the new 3D printed axel in as far as it will go (The oval part will fit in either way around) so the round disc is touching the metal leg frame.Replace the nut and bolt and tighten.(optional)...

thingiverse

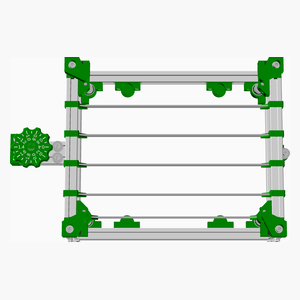

Frame of the press - [aluminum profile 20x20 with V-slot](https://aliexpress.ru/item/1005003367614421.html). I have 300 mm. 200-250 mm is also suitable if you ok with a smaller working range of heights. In the axial hole of the profile on the "up"...

prusaprinters

The washers should prevent tearing outside of the rings.Place the foil onto the telescope frame, looping the washers around the posts. Insert the mirror tower and adjust as needed. Use scissors to cut the sun shield into the desired shape. ...For best...

thingiverse

I will be drawing a sliding frame that'll finish off making it into a complete & otherwise conventional vice. That'll happen hopefully soon. You'll need fourteen 3 mm bolts to lock the smaller parts together, and trim them all to the correct...

prusaprinters

*"Main-Large Token Tray 1x5 - Tall.stl" - x *"Main-Large Token Tray 1x5.stl" - x1 *"Main-Large Tray.stl" - x1 - This tray and "Main-Large Token Tray 1x5.stl" can be replaced with another "Main-Large Token Tray 1x5 - Tall.stl", I wanted a place to...

prusaprinters

The magnets are generally glued to the holding frame in the hard drive but with careful prying with a thin blade like a putty knife, you can separate them without damaging them. In this upgrade they do not need to be cosmetically perfect since they...

thingiverse

I have a 50 yr old A frame that has vertical cedar siding for some of its interior walls. The joints cause issues since a lot of the outlets ended up positioned somewhere over a joint. It not only looks bad but I get quite a draft through those holes...

prusaprinters

Exterior dimensions are 66x66x66mm. To assemble: 1) Print the following pieces and gather non printed parts: 6 x outerface (the "Merry Christmas" face is optional and requires multi-extrusion) 6 x innerface 6 x slider 6 x slider2 6 x nut trap...

thingiverse

Attach the top extrusions to the rest of the frame.  <span></span> [Top](#TOP) --- <a...

thingiverse

The system has about 15ms of measured lag, which is about 1 frame in a game. The base station appears as a game controller for a PC. Building the wireless system requires some electrical skills. The wireless side was developed by me and my friend...

thingiverse

The motor house is big enough, and the framing and decking were designed for easy redesign and modification without the need for significant reprint. The prototype uses a remote 12V power supply (located on Level A) culled from an old PC together...

prusaprinters

through the foam seal between the plastic cover and the steel frame at the left side of the rear window. Guide the cable near the distributor box, crimp on the female two-pole and connect to the open connector on the box. Test everything.Re-attach...

thingiverse

Update April 27, 2020 Added Version C8.1 with an optimized rubber band holder (Thanks to Corona-Hub-Vaihingen!) Update April 18, 2020 Added a stack of two frames (Thanks to Phillip Stinner!) This is a clear development from our first version of the...

prusaprinters

You can support the project on the Indiegogo site (https://www.indiegogo.com/projects/nybble-world-s-cutest-open-source-robotic-kitten#/) where you can buy a full kit or even just the electronics board. Source code and schematic is located at...

prusaprinters

The upper and lower rails provided will clip into a standard basement window frame and accept a ¼ inch MDF board. You will need to cut a board to the appropriate height dimensions for your application. The slot in the upper rail is deeper than the...

prusaprinters

I also found thebeetleuk's clever design (https://www.thingiverse.com/thing:2212749) which allowed the tables to be easily and securely stacked but also removable for easy access to the printer. Like I do with some of my designs, I started with these...

thingiverse

- 2x Adjustable Spool holder bracket (Requires 1x M3 thermal insert each) - 2x External Spool Holder Plate - 2x Bearing Flange (to secure the bearings to the adjustable spool holder brackets) - 2x Internal Spool Holder Plate - 1x Frame Mount Gasket...

thingiverse

First, you just have to mount the remote to the frame of your printer. Then, you have to mount a rubber stick to the printhead which is pressing the button of the remote and triggers the picture. The problem now is to get the printhead to move to...

thingiverse

(2)/(3) May design as one piece, with very limited time frame available every day, I will leave the design here as they works just fine on my B1SEPlus. Remix them as you like :) This is my first post on Thingiverse and hopefully bring out more...

prusaprinters

The top and bottom of the phone fall into place in matching recesses in the frame. The phone can be tilted at angles from 20 degrees to 75 degrees.</p><p>The stand can be made with two vertical parts connected by short beams (sticks) or as a...

prusaprinters

If you have one of the Prusa MK3 printer series printers, I highly recommend you check out Grégoire's excellent enhancements to this printer:Bear Frame Upgrade 2.1Bear Extruder and X Axis (BearExxa) - This is v1; hopefully by the time you are seeing...

thingiverse

Checking "Slow" will slow down the Drawing for one frame only - it sort of simulates/animates the print 6. Try selecting Single Layer, and From-To. Layer shows only 1 layer. From-To shows by individual segments. The corresponding lines of G-Code are...